- PLA Basic

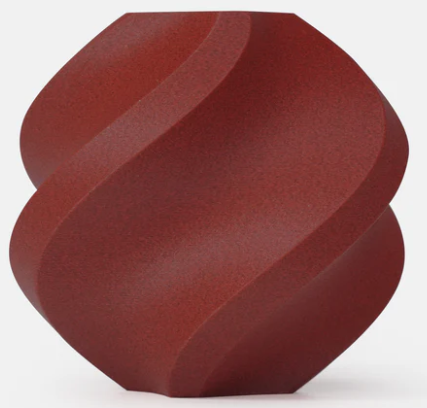

- PLA Matte

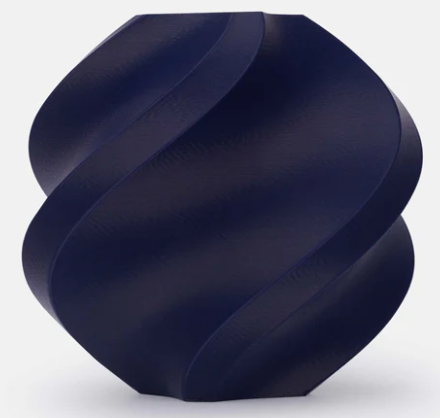

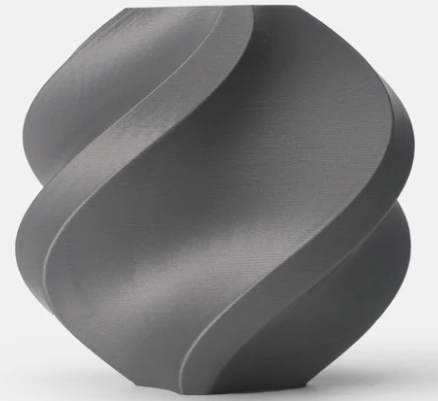

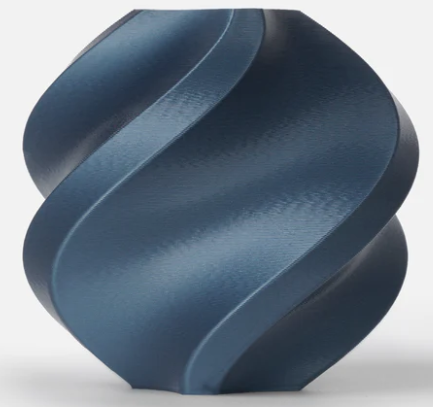

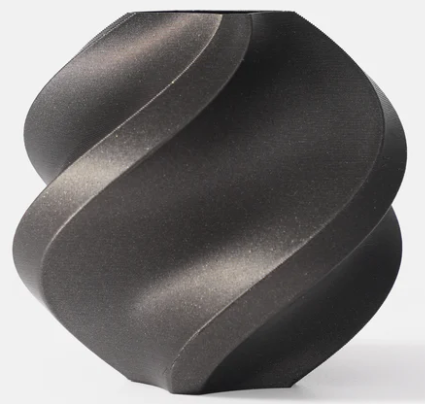

- PLA-CF

- PLA Marble

- PLA Wood

- ASA-CF

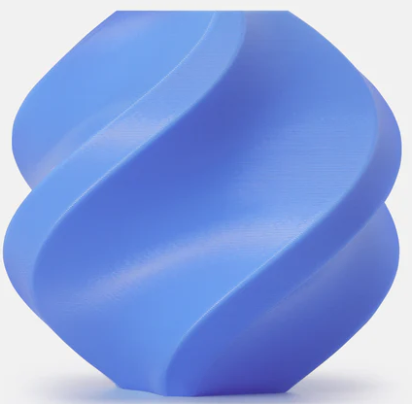

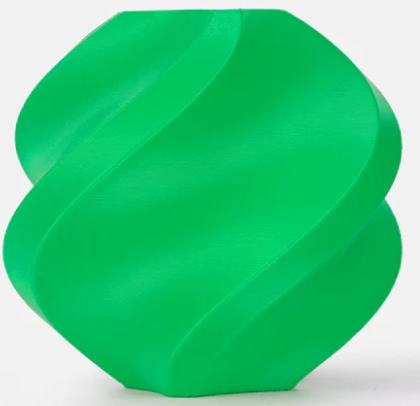

- PETG

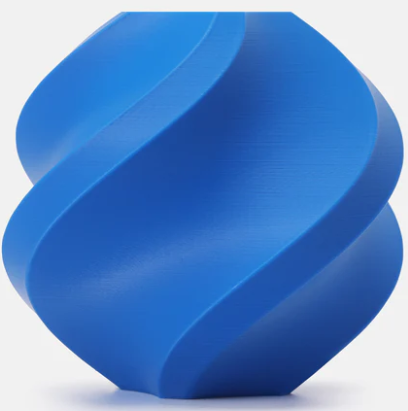

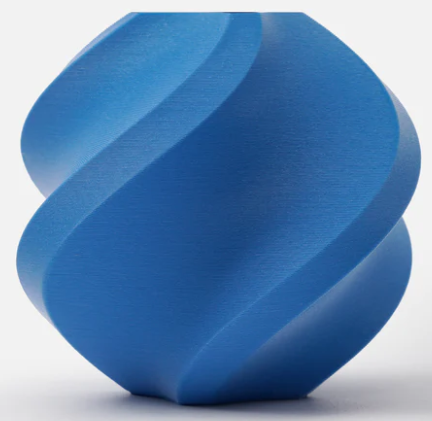

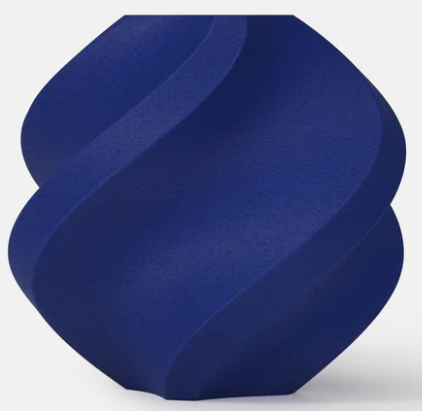

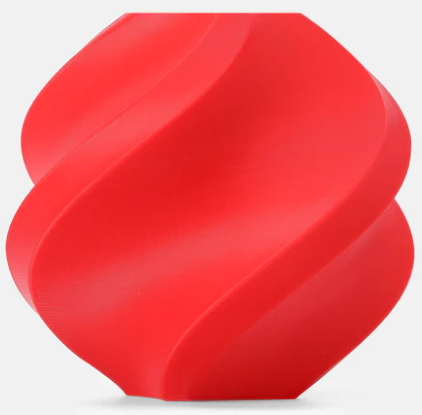

- TPU 95A

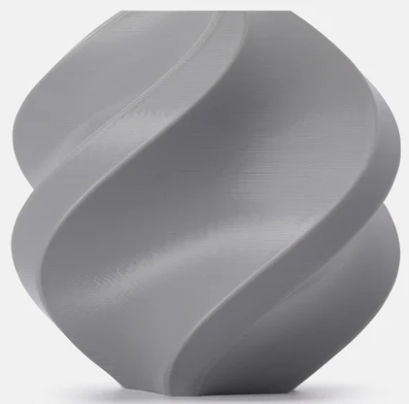

- ASA

- PC

- PETG-CF

- TPU 68D

- ABS

- PLA Glow

- ABS-GF

- PLA Metal

- ASA Aero

- PETG Translucent

- PLA Sparkle

- PLA Aero

- PA6-CF

- PLA Galaxy

- PET-CF

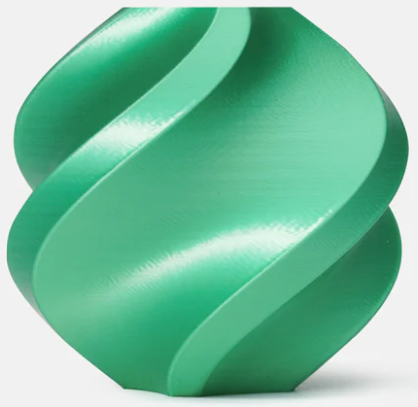

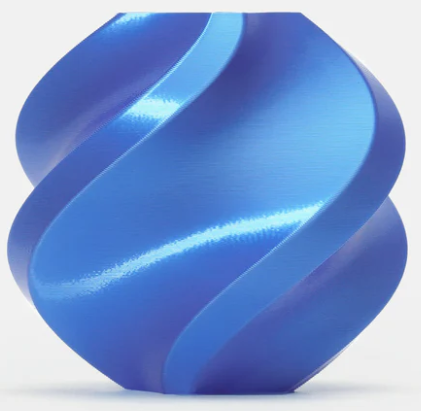

- PLA Silk

- PAHT-CF

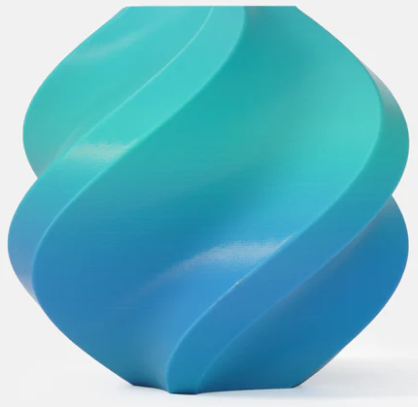

- PLA Gradient

- PA6-GF

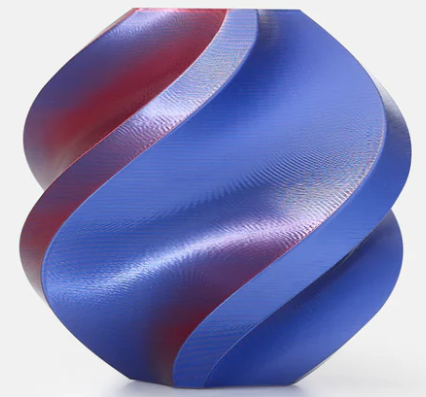

- PLA Silk Dual Color

- PPA-CF

Material Description

Polylactic Acid (PLA)

PLA filament stands out for its high print speed, and excellent appearance. Experience the benefits of smooth and flawless prints with superior quality that exceeds expectations.

PLA Basic Hex Code Table

| Color | Hex Code | Display |

| Jade White | #FFFFFF | |

| Beige | #F7E6DE | |

| Gold | #E4BD68 | |

| Silver | #A6A9AA | |

| Gray | #8E9089 | |

| Bronze | #847D48 | |

| Brown | #9D432C | |

| Cocoa Brown | #6F5034 | |

| Maroon Red | #9D2235 | |

| Red | #C12E1F | |

| Magenta | #EC008C | |

| Pink | #F55A74 | |

| Hot Pink | #F5547C | |

| Orange | #FF6A13 | |

| Pumpkin Orange | #FF9016 | |

| Sunflower Yellow | #FEC600 | |

| Yellow | #F4EE2A | |

| Bright Green | #BECF00 | |

| Bambu Green | #00AE42 | |

| Mistletoe Green | #3F8E43 | |

| Turquoise | #00B1B7 | |

| Cyan | #0086D6 | |

| Blue | #0A2989 | |

| Cobalt Blue | #0056B8 | |

| Purple | #5E43B7 | |

| Indigo Purple | #482960 | |

| Blue Gray | #5B6579 | |

| Light Gray | #D1D3D5 | |

| Dark Gray | #545454 | |

| Black | #000000 |

| Physical Properties | |

| Density | 1.24 g/cm³ |

| Vicat Softening Temperature | 57 °C |

| Heat Deflection Temperature | 57 °C |

| Melting Temperature | 160 °C |

| Melt Index | 42.4 ± 3.5 g/10 min |

| Mechanical Properties | |

| Tensile Strength | 35 ± 4 MPa |

| Breaking Elongation Rate | 12.2 ± 1.8 % |

| Bending Modulus | 2750 ± 160 MPa |

| Bending Strength | 76 ± 5 MPa |

| Impact Strength | 26.6 ± 2.8 kJ/m² |

Available Colors

| Max. Size: | 256x256x256 mm |

| Ship within: | 1 working days |

Material Description

PLA Matte Hex Code Table

| Color | Hex Code | Display |

| Ivory White | #FFFFFF | |

| Latte Brown | #D3B7A7 | |

| Desert Tan | #E8DBB7 | |

| Ash Gray | #9B9EA0 | |

| Lilac Purple | #AE96D4 | |

| Sakura Pink | #E8AFCF | |

| Mandarin Orange | #F99963 | |

| Lemon Yellow | #F7D959 | |

| Scarlet Red | #DE4343 | |

| Dark Red | #BB3D43 | |

| Dark Brown | #7D6556 | |

| Dark Green | #68724D | |

| Grass Green | #61C680 | |

| Ice Blue | #A3D8E1 | |

| Marine Blue | #0078BF | |

| Dark Blue | #042F56 | |

| Charcoal | #000000 |

| Physical Properties | |

| Density | 1.31 g/cm³ |

| Vicat Softening Temperature | 63 °C |

| Heat Deflection Temperature | 58 °C |

| Melting Temperature | 163 °C |

| Melt Index | 39.4 ± 3.2 g/10 min |

| Mechanical Properties | |

| Tensile Strength | 30 ± 5 MPa |

| Breaking Elongation Rate | 14.8 ± 4.2 % |

| Bending Modulus | 2360 ± 250 MPa |

| Bending Strength | 53 ± 6 MPa |

| Impact Strength | 19.2 ± 3.7 kJ/m² |

Available Colors

| Max. Size: | 256x256x256 mm |

| Ship within: | 1 working days |

Material Description

PLA-CF

PLA-CF is carbon fiber reinforced PLA with improved stiffness and strength. PLA-CF is easy to print and beginner-friendly like regular PLA. It is AMS compatible with low clogging risk at high-speed printing. The prints are in matte finish with almost invisible layer lines, which make it suitable for printing general engineering parts or models requiring a better appearance, like bike frames, brackets and toys.

Carbon fiber texture & Minimized layer lines

The addition of carbon fiber gives prints a unique matte finish and effectively hides layer lines, providing a smooth, premium look.

Display of Prints

PLA-CF could be paired with any PLA series filament to make your prints more colorful and achieve various texture requirements.

Improved mechanical properties

PLA-CF exceeds the mechanical properties of PLA Matte in XY Bending Strength, Z Bending Strength, XY Bending Modulus, Z Bending Modulus, XY Impact Strength, and Z Impact Strength by between 20% and 115%, making it more suitable for printing models with higher strength requirements.

Mechanical Properties Comparison

| PLA Matte | PLA-CF | Improved % | |

| Tensile Strength - XY/MPa | 32 | 38 | 19% |

| Tensile Strength - Z/MPa | 25 | 26 | 4% |

| Bending Strength - XY/MPa | 53 | 89 | 68% |

| Bending Strength - Z/MPa | 32 | 49 | 53% |

| Bending Modulus - XY/MPa | 2360 | 3950 | 67% |

| Bending Modulus - Z/MPa | 2040 | 2260 | 10% |

| Impact Strength - XY/(kJ/m²) | 19.2 | 23.2 | 20% |

| Impact Strength - Z/(kJ/m²) | 6.6 | 7.8 | 18% |

Stablized printing dimension

PLA-CF features low shrinkage and warping resistance to achieve a perfect matching accuracy between prints parts.

PLA-CF Hex Code Table

| Color | Hex Code | Display |

| Burgundy Red | #951e23 | |

| Matcha Green | #5c9748 | |

| Jeans Blue | #6e88bc | |

| Royal Blue | #2842AD | |

| Iris Purple | #69398E | |

| Lava Gray | #4d5054 | |

| Black | #000000 |

| Physical Properties | |

| Density | 1.22 g/cm³ |

| Vicat Softening Temperature | 69 °C |

| Heat Deflection Temperature | 55 °C |

| Melting Temperature | 165 °C |

| Melt Index | 3.7 ± 0.6 g/10 min |

| Mechanical Properties | |

| Tensile Strength | 38 ± 4 MPa |

| Breaking Elongation Rate | 8.4 ± 3.2 % |

| Bending Modulus | 3950 ± 190 MPa |

| Bending Strength | 89 ± 4 MPa |

| Impact Strength | 23.2 ± 3.7 kJ/m² |

Available Colors

| Max. Size: | 256x256x256 mm |

| Ship within: | 1 working days |

Material Description

Polylactic Acid Marble (PLA Marble)

PLA Marble mimics the appearance of natural stone.

With inorganic particles in its composition, it offers a vivid stone-like texture that resembles marble, granite, or bricks. It adds a touch of nature to your prints and provides a stunning finish for your projects.

PLA Marble Hex Code Table

| Color | Hex Code | Display |

| White Marble | #F7F3F0 | |

| Red Granite | #AD4E38 |

| Physical Properties | |

| Density | 1.22 g/cm³ |

| Vicat Softening Temperature | 57 °C |

| Heat Deflection Temperature | 56 °C |

| Melting Temperature | 156 °C |

| Melt Index | 32.2 ± 4.5 g/10 min |

| Mechanical Properties | |

| Tensile Strength | 33 ± 4 MPa |

| Breaking Elongation Rate | 6.7 ± 0.5 % |

| Bending Modulus | 2920 ± 180 MPa |

| Bending Strength | 75 ± 5 MPa |

| Impact Strength | 24.0 ± 2.5 kJ/m² |

Available Colors

| Max. Size: | 256x256x256 mm |

| Ship within: | 1 working days |

Material Description

PLA Wood

PLA Wood is a mixer of our high-quality PLA with fine wood powder to give your 3D prints a realistic wood-like appearance and texture. Experience the rich, grainy feel of natural wood with every print, as the filament replicates authentic wood tones and textures. PLA Wood provides a stunning, elegant finish that elevates your creations with an organic, handcrafted look.

Feels Like Real Wood

PLA Wood offers a smooth yet slightly grainy texture, with the feel of real wood. With natural wood-like colors and a subtle scent, your models will embody the essence of genuine wood. Perfect for projects that demand a true-to-life wood aesthetic, PLA Wood blends beauty and authenticity for a natural finish.

Matte Finish, Fine Texture

The matte finish of PLA Wood effectively conceals layer lines, delivering smoother, more refined prints. Its seamless surface enhances the overall aesthetic, giving your creations an authentic, real-wood appearance.

Enhance Your PLA Models with Wood Accents

PLA Wood integrates seamlessly with other Bambu PLA filaments like PLA Basic and PLA Matte, allowing you to combine natural wood textures with vibrant colors. Mix and match textures in a single print to unlock endless creative possibilities and bring your designs to life.

PLA Wood Hex Code Table

| Color | Hex Code | Display |

| Black Walnut | #4F3F24 | |

| Rosewood | #4C241C | |

| Clay Brown | #995F11 | |

| Classic Birch | #918669 | |

| White Oak | #D6CCA3 | |

| Ochre Yellow | #C98935 |

| Physical Properties | |

| Density | 1.21g/cm³ |

| Vicat Softening Temperature | 64 °C |

| Heat Deflection Temperature | 57 °C |

| Melting Temperature | 156 °C |

| Melt Index | 29.4 ± 1.7 g/10 min |

| Mechanical Properties | |

| Tensile Strength | 26 ± 5 MPa |

| Breaking Elongation Rate | 15.3 ± 3.1 % |

| Bending Modulus | 2780 ± 120 MPa |

| Bending Strength | 55 ± 4 MPa |

| Impact Strength | 15.7 ± 3.7 kJ/m² |

Available Colors

| Max. Size: | 256x256x256 mm |

| Ship within: | 1 working days |

Material Description

Carbon Fiber Reinforced Acrylonitrile Atyrene Acrylate (ASA-CF)

Engineered for harsh outdoor conditions, ASA-CF offers exceptional weather and UV resistance, retaining the advantages of ASA while adding carbon fiber for increased stiffness and dimensional stability. This makes it the perfect choice for large-scale models requiring durability and precision in demanding environments.

Superior Outdoor Durability

ASA-CF stands out as one of the top materials for outdoor use, with excellent resistance to harsh weather and UV exposure. Reinforced with carbon fiber, it’s ideal for creating durable garden tools, outdoor furniture, and protective enclosures for electronics.

Optimized for Large Models

With carbon fiber reducing warping, ASA-CF ensures outstanding dimensional stability, making it ideal for large models or parts that require high precision, such as those in assembly.

Sleek Matte Finish

The smooth matte surface, with minimal visible layer lines, gives ASA-CF a refined, natural appearance, perfect for detailed models like planters and other outdoor decor.

Enhanced Stiffness for High Load-Bearing Parts

ASA-CF offers 67% more stiffness compared to standard ASA, making it the go-to material for parts that need to withstand significant load and resist bending, such as camping accessories, plant stands or other outdoor furniture.

| Filament Type | ASA-CF | ASA |

| Stiffness (Bending Modulus - XY) | 3740 MPa | 1920 MPa |

| Layer Adhesion (Impact Strength - Z) | 9.4 kJ/m² | 4.9 kJ/m² |

| Physical Properties | |

| Density | 1.02 g/cm³ |

| Vicat Softening Temperature | 108 °C |

| Heat Deflection Temperature | 110 °C |

| Melting Temperature | 210 °C |

| Melt Index | 1.74 ± 0.3 g/10 min |

| Mechanical Properties | |

| Tensile Strength | 34 ± 3 MPa |

| Breaking Elongation Rate | 9.6 ± 1.4 % |

| Bending Modulus | 3740 ± 130 MPa |

| Bending Strength | 72 ± 5 MPa |

| Impact Strength | 14.0 ± 2.2 kJ/m² |

Available Colors

| Max. Size: | 256x256x256 mm |

| Ship within: | 1 working days |

Material Description

Polyethylene Terephthalate (PETG)

Offering greater durability and toughness than PLA, PETG is the ideal choice for creating long-lasting items with an improved finish and faster production times.

Smooth, Soft Texture

PETG HF provides a smooth texture and consistent gloss at any printing speed, ensuring uniformity and sharp details in every print.

Ready for Outdoor Use

PETG HF maintains the inherent strengths of regular PETG, providing superior resistance to water, UV, and temperatures. Tougher and more durable than PLA, with higher temperature resistance, it's the perfect choice for printing outdoor items such as planter pots, bird cages, watering cans, and automotive parts. Additionally, it's ideal for outdoor toys that require long-term exposure and the ability to withstand impacts, collisions, and falls.

PETG HF Hex Code Table

| Color | Hex Code | Display |

| Yellow | #FFD00B | |

| Orange | #F75403 | |

| Green | #00AE42 | |

| Red | #EB3A3A | |

| Blue | #002E96 | |

| Black | #000000 | |

| White | #FFFFFF | |

| Cream | #F9DFB9 | |

| Lime Green | #6EE53C | |

| Forest Green | #39541A | |

| Lake Blue | #1F79E5 | |

| Peanut Brown | #875718 | |

| Gray | #ADB1B2 | |

| Dark Gray | #515151 |

| Physical Properties | |

| Density | 1.28 g/cm³ |

| Vicat Softening Temperature | 70 °C |

| Heat Deflection Temperature | 69 °C |

| Melting Temperature | 214 °C |

| Melt Index | 28.2 ± 2.7 g/10 min |

| Mechanical Properties | |

| Tensile Strength | 34 ± 4 MPa |

| Breaking Elongation Rate | 8.6 ± 1.2 % |

| Bending Modulus | 2050 ± 120 MPa |

| Bending Strength | 64 ± 3 MPa |

| Impact Strength | 31.5 ± 2.2 kJ/m² |

Available Colors

| Max. Size: | 256x256x256 mm |

| Ship within: | 1 working days |

Material Description

Thermoplastic Polyurethane 95A (TPU 95A)

TPU HF is an exceptionally soft and flexible filament with extraordinary impact resistance, enabling you to print parts that need withstand impact, collision, and falling.

TPU 95A HF Hex Code Table

| Color | Hex Code | Display |

| White | #FFFFFF | |

| Yellow | #F3E600 | |

| Blue | #0072CE | |

| Red | #C8102E | |

| Gray | #898D8D | |

| Black | #101820 |

| Physical Properties | |

| Density | 1.22 g/cm³ |

| Vicat Softening Temperature | N / A |

| Heat Deflection Temperature | N / A |

| Melting Temperature | 183 °C |

| Melt Index | 36.5 ± 2.6 g/10 min |

| Mechanical Properties | |

| Tensile Strength | 27.3 ± 0.8 MPa |

| Breaking Elongation Rate | > 650% |

| Bending Modulus | N / A |

| Bending Strength | N / A |

| Impact Strength | N / A |

Available Colors

| Max. Size: | 256x256x256 mm |

| Ship within: | 1 working days |

Material Description

Acrylonitrile Styrene Acrylate (ASA)

ASA is a highly durable material that offers exceptional UV, weather, mechanical, and thermal resistance. Its unique combination of properties makes it an ideal material for printing outdoor models (plant signs, mailboxes, wind vanes, etc.) and structural parts that require long-term exposure to challenging outdoor conditions.

Extraordinary Weather & UV Resistance

ASA offers extraordinary UV, oxidation, and aging resistance, providing effective protection against breakage and color degradation when used outdoors for long-term purposes.

Tough and Durable

Suitable for outdoor applications and regular structural requirements due to its toughness and high impact strength.

Better Temperature Resistance

Compared to normal PETG or ABS, ASA can remain in shape even at a temperature of 100°C.

Frequently Asked Questions

1. What's the difference between ABS and ASA?

| ABS | ASA | |

| Composition | acrylonitrile - butadiene - styrene | acrylonitrile - styrene - acrylate |

ASA is a modified version of ABS that contains an additional acrylate component, which improves its weather adaptability and UV resistance.

ASA retains the impact resistance and processability of ABS while providing better resistance to fading, yellowing, and degradation from sunlight exposure. Both of them may release pungent and unpleasant odors during printing, but the pungent odor of ASA is notably lighter than ABS.

2. What is the difference applications between ABS and ASA?

ASA is ideal for outdoor applications, such as automotive exterior parts, signage, and outdoor equipment, thanks to its enhanced weather resistance and color stability. ABS is a versatile material with excellent mechanical properties that is commonly used for indoor applications.

3. What are the similarities between ABS and ASA?

In terms of physical and mechanical properties, both exhibit good impact resistance and high tensile strength, with almost the same levels of strength, toughness, and stiffness. Both ABS and ASA may release pungent and unpleasant odors during printing and the same warping tendency and enclosed printer requirement when printing large-size and/or high infill density models.

ASA Hex Code Table

| Color | Hex Code | Display |

| White | #FFFAF2 | |

| Gray | #8A949E | |

| Red | #E02928 | |

| Green | #00A6A0 | |

| Blue | #2140B4 | |

| Black | #000000 |

| Physical Properties | |

| Density | 1.05 g/cm³ |

| Vicat Softening Temperature | 106 °C |

| Heat Deflection Temperature | 100 °C |

| Melting Temperature | 210 °C |

| Melt Index | 7.0 ± 0.8 g/10 min |

| Mechanical Properties | |

| Tensile Strength | 37 ± 3 MPa |

| Breaking Elongation Rate | 9.2 ± 1.4 % |

| Bending Modulus | 1920 ± 130 MPa |

| Bending Strength | 65 ± 5 MPa |

| Impact Strength | 41.0 ± 2.3 kJ/m² |

Available Colors

| Max. Size: | 256x256x256 mm |

| Ship within: | 1 working days |

Material Description

Polycarbonate

Product Features

- Exceptional Thermal Resistance

- Excellent Mechanical Properties

- High Impact Strength and Durability

- Suitable for Engineering Purpose

| Physical Properties | |

| Density | 1.20 g/cm³ |

| Vicat Softening Temperature | 119 °C |

| Heat Deflection Temperature | 117 °C |

| Melting Temperature | 228 °C |

| Melt Index | 32.2 ± 2.9 g/10 min |

| Mechanical Properties | |

| Tensile Strength | 55 ± 4 MPa |

| Breaking Elongation Rate | 3.8 ± 0.3 % |

| Bending Modulus | 2310 ± 70 MPa |

| Bending Strength | 108 ± 4 MPa |

| Impact Strength | 34.8 ± 2.1 kJ/m² |

Available Colors

| Max. Size: | 256x256x256 mm |

| Ship within: | 1 working days |

Material Description

PETG-CF

PETG-CF is a composite material consisting of PETG and carbon fiber. The new formula greatly improved printing quality by reducing clumping compared to traditional PETG. With the addition of carbon fiber, PETG-CF offers improved strength while maintaining good toughness and a shiny look. It is an ideal material for drone parts, racing models, and various functional parts that require both high performance, especially impact strength, and a sleek appearance.

Less clumping and stringing

PETG-CF is improved with a modified formula that specifically addresses the issue of clumping and sticking to nozzle during PETG printing.

Premium print surface

Carbon fiber brings advanced texture to the print surface, while retaining the shine of PETG itself.

Carbon Fiber Texture

Carbon fiber brings soft reflection, minimal layer lines and a unique delicate texture.

Shiny Finish

Different from PLA-CF's matte finish, PETG-CF offers a shiny finish and thus one more choice.

Strong XY Performance

The addition of carbon fiber also significantly enhances the XY strength of PETG without sacrificing layer bonding.

High Flexibility

Compared to other carbon fiber materials, PETG-CF exhibits exceptional toughness

and is less prone to fracture under external stress and impact.

PETG-CF Hex Code Table

| Color | Hex Code | Display |

| Brick Red | #9f332a | |

| Violet Purple | #583061 | |

| Indigo Blue | #324585 | |

| Malachite Green | #16b08e | |

| Black | #000000 | |

| Titan Gray | #565656 |

| Physical Properties | |

| Density | 1.25 g/cm³ |

| Vicat Softening Temperature | 85 °C |

| Heat Deflection Temperature | 74 °C |

| Melting Temperature | 225 °C |

| Melt Index | 19.3 ± 2.4 g/10 min |

| Mechanical Properties | |

| Tensile Strength | 35 ± 5 MPa |

| Breaking Elongation Rate | 10.4 ± 0.6 % |

| Bending Modulus | 2910 ± 260 MPa |

| Bending Strength | 70 ± 5 MPa |

| Impact Strength | 41.2 ± 2.6 kJ/m² |

Available Colors

| Max. Size: | 256x256x256 mm |

| Ship within: | 1 working days |

Material Description

Thermoplastic Polyurethane 68D (TPU 68D)

With a Shore hardness of 68D, TPU combines exceptional toughness with the flexibility and durability of TPU. It's ideal for printing durable, impact-resistant parts like protective cases, phone covers, door stoppers, sports equipment, automotive parts, and much more!

TPU Hex Code Table

| Color | Hex Code | Display |

| Red | #ED0000 | |

| Yellow | #F9EF41 | |

| Blue | #5898DD | |

| Neon Green | #90FF1A | |

| White | #FFFFFF | |

| Gray | #939393 | |

| Black | #000000 |

| Physical Properties | |

| Density | 1.26 g/cm³ |

| Vicat Softening Temperature | N / A |

| Heat Deflection Temperature | N / A |

| Melting Temperature | 183 °C |

| Melt Index | 21.8 ± 0.3 g/10 min |

| Mechanical Properties | |

| Tensile Strength | 22.4 ± 0.6 MPa |

| Breaking Elongation Rate | >650 % |

| Bending Modulus | N / A |

| Bending Strength | N / A |

| Impact Strength | N / A |

Available Colors

| Max. Size: | 256x256x256 mm |

| Ship within: | 1 working days |

Material Description

Acrylonitrile Butadiene Styrene (ABS)

ABS is a dependable 3D printing material renowned for its exceptional stability, durability, and high impact resistance. Additionally, this filament also boasts excellent heat resistance, making it ideal for projects involving moderate temperatures. With its versatile properties, Bambu ABS filament stands as an excellent choice for a wide range of 3D printing applications.

Strong & Durable

As one of the most widely used filaments, ABS comes with excellent mechanical properties that make it stronger than normal PLA and PETG. It is ideal for creating functional parts, prototypes, and standard engineering components, ensuring long life and reliability.

Impressive Heat Resistance

ABS filament offers exceptional heat resistance (Heat Deflection Temperature: 87 °C) coupled with commendable mechanical properties. This makes it an outstanding choice for everyday functional parts that require high-temperature resistance.

Water-Resistant

Boasting excellent water-resistant performance, ABS ensures relatively long-lasting durability when used in a wet environment.

Tough with High Impact Resistance

ABS is exceptionally robust, and its prints can withstand multiple impacts, collisions, and falls. It exhibits good impact resistance even at low temperatures.

ABS Hex Code Table

| Color | Hex Code | Display |

| Beige | #DFD1A7 | |

| Lavender | #7248BD | |

| Olive | #789D4A | |

| Tangerine Yellow | #FFC72C | |

| Azure | #489FDF | |

| Navy Blue | #0C2340 | |

| White | #FFFFFF | |

| Silver | #87909A | |

| Red | #D32941 | |

| Orange | #FF6A13 | |

| Yellow | #FCE900 | |

| Mint | #7AE1BF | |

| Bambu Green | #00AE42 | |

| Blue | #0A2CA5 | |

| Purple | #AF1685 | |

| Black | #000000 |

| Physical Properties | |

| Density | 1.05 g/cm³ |

| Vicat Softening Temperature | 94 °C |

| Heat Deflection Temperature | 87 °C |

| Melting Temperature | 200 °C |

| Melt Index | 34.2 ± 3.8 g/10 min |

| Mechanical Properties | |

| Tensile Strength | 33 ± 3 MPa |

| Breaking Elongation Rate | 10.5 ± 1.0 % |

| Bending Modulus | 1880 ± 110 MPa |

| Bending Strength | 62 ± 4 MPa |

| Impact Strength | 39 ± 3.6 kJ/m² |

Available Colors

| Max. Size: | 256x256x256 mm |

| Ship within: | 1 working days |

Material Description

PLA Glow

PLA Glow stands out due to its incorporation of a unique additive: luminous powder. This variant retains the familiar qualities of traditional PLA, including easy printing, high quality, and exceptional overall mechanical properties. What sets PLA Glow apart is its distinctive feature - it glows in the dark. This makes it the optimal selection for crafting luminous nameplates, logos, jewelry, and various models that require a captivating glow effect.

Unique Glow in Low Light Conditions

PLA Glow incorporates a distinct additive: luminous powder, which imparts a special property to printed objects, causing them to emit a captivating glow in the dark.

PLA Glow Hex Code Table

| Color | Hex Code | Display |

| Glow Green | #A1FFAC | |

| Glow Yellow | #F8FF80 | |

| Glow Pink | #F17B8F | |

| Glow Blue | #7AC0E9 | |

| Glow Orange | #FF9D5B |

* The hex code indicates the daytime color of PLA Glow.

| Physical Properties | |

| Density | 1.26 g/cm³ |

| Vicat Softening Temperature | 56 °C |

| Heat Deflection Temperature | 55 °C |

| Melting Temperature | 155 °C |

| Melt Index | 23.3± 2.4 g/10 min |

| Mechanical Properties | |

| Tensile Strength | 32 ± 3 MPa |

| Breaking Elongation Rate | 8.6 ± 1.2 % |

| Bending Modulus | 2640 ± 130 MPa |

| Bending Strength | 76 ± 4 MPa |

| Impact Strength | 27.3 ± 2.2 kJ/m² |

Available Colors

| Max. Size: | 256x256x256 mm |

| Ship within: | 1 working days |

Material Description

Glass Fiber Reinforced ABS (ABS-GF)

ABS-GF is a glass fiber-reinforced ABS filament, enhanced in both mechanical and aesthetic properties. Compared with regular ABS, ABS-GF outperforms in strength, stiffness, temperature resistance and dimensional stability, while being less prone to deformation and warping. Glass fiber imparts a smooth matte finish with micro-spot gloss, blurring layer lines. ABS-GF is ideal for both mechanical parts and decorations due to the inherited water resistance, wear resistance, durability and vibrant colors.

Enhanced Strength and Stiffness

ABS-GF outclasses regular ABS in strength and stiffness, making it perfect for load-bearing and bending-resistance parts.

| ABS |

ABS-GF |

Improvement % | |

| Stiffness (Bending Modulus - XY) | 1880 MPa |

2860 MPa |

52.1% |

| Strength (Bending Strength - XY) | 64 MPa |

68 MPa |

6.3% |

| Layer Strength (Bending Strength - Z) | 39 MPa |

46 MPa |

17.9% |

| Heat Resistance (HDT, 0.45 MPa) | 87 °C |

99 °C |

13.8% |

Greater Dimensional Stability

Glass fiber reinforcement gives ABS-GF better dimensional stability than regular ABS, minimizing warping and deformation during printing. This makes it ideal for intricate mechanical assembly parts or geometric components.

Fine Matte Finish

The seamless matte finish, coupled with nearly invisible layer lines, gives ABS-GF a smooth appearance, making it ideal for decorative and fine-grained parts.

Water Resistance & Built to Last

With improved water resistance and durability, ABS-GF is ideal for printing long-lasting production and household items, like mechanical casings, connectors and molds.

ABS-GF Hex Code Table

| Color | Hex Code | Display |

| White | #FFFFF | |

| Gray | #C6C6C6 | |

| Yellow | #FFE133 | |

| Orange | #F48438 | |

| Red | #E83100 | |

| Green | #61BF36 | |

| Blue | #0C3B95 | |

| Black | #000000 |

| Physical Properties | |

| Density | 1.08 g/cm³ |

| Vicat Softening Temperature | 103 °C |

| Heat Deflection Temperature | 99 °C |

| Melting Temperature | 202 °C |

| Melt Index | 7.56 ± 1.4 g/10 min |

| Mechanical Properties | |

| Tensile Strength | 36 ± 3 MPa |

| Breaking Elongation Rate | 6.3% ± 1.2% |

| Bending Modulus | 2860 ± 130 MPa |

| Bending Strength | 68 ± 4 MPa |

| Impact Strength | 14.5 ± 1.5 kJ/m² |

Available Colors

| Max. Size: | 256x256x256 mm |

| Ship within: | 1 working days |

Material Description

PLA Metal

PLA Metal is a metallic textured filament designed to enhance the aesthetic of your prints. It is designed to mimic the surface texture of metal, but it does not contain actual metal fillers.

With its advanced metallic shine, this filament offers a professional and high-end finish and a touch of sophistication to your prints while retaining almost the same comprehensive performance of regular PLA.

PLA Metal Hex Code Table

| Color | Hex Code | Display |

| Iridium Gold Metallic | #B39B84 | |

| Copper Brown Metallic | #AA6443 | |

| Oxide Green Metallic | #1D7C6A | |

| Cobalt Blue Metallic | #39699E | |

| Iron Gray Metallic | #43403D |

| Physical Properties | |

| Density | 1.25 g/cm³ |

| Vicat Softening Temperature | 62 °C |

| Heat Deflection Temperature | 62 °C |

| Melting Temperature | 160 °C |

| Melt Index | 38.6 ± 3.7 g/10 min |

| Mechanical Properties | |

| Tensile Strength | 34 ± 4 MPa |

| Breaking Elongation Rate | 14.7 ± 1.5 % |

| Bending Modulus | 2290 ± 210 MPa |

| Bending Strength | 66 ± 3 MPa |

| Impact Strength | 58.9 ± 3.4 kJ/m² |

Available Colors

| Max. Size: | 256x256x256 mm |

| Ship within: | 1 working days |

Material Description

ASA Aero

ASA Aero is a self-foaming material renowned for its exceptional durability and toughness. Its heat-sensitive foaming allows for controlled model density, resulting in feather-light print models. Additionally, it boasts extraordinary resistance to temperature, water, and UV rays. With these unique properties, it is ideal for printing long-lasting outdoor models and weight-sensitive projects, such as RC planes.

Impact Resistance & Built to Last

Compared with other foaming filament, ASA Aero is tougher with higher layer strength, making it more resistant to impact, collision, and falling, perfect for high-stress demanding applications.

Ultra-lightweight, Controllable Density

Only 50%-75% the density of regular ASA prints, ASA Aero is as light as feather, designed for weight-sensitive objects, such as RC planes and unmanned aerial vehicles (UAVs). With controllable foaming characteristic, ASA Aero achieves lower density of prints by increasing printing temperature or lowering flow rate.

The average density of prints will vary with changes in parameters such as actual printing temperature, flow rate ratio, printing speed, model size, wall thickness and infill density.

|

Parameter Setting |

Average Density |

|

| Printing Temperature | Increases ↗ | Decreases ↘ |

| Printing Speed | Increases ↗ | Stable or Increases ↗ |

| Flow Rate Ratio | Increases ↗ | Increases ↗ |

| Model Size | Increases ↗ | Decreases ↘ |

| Wall Thickness(Wall loops) | Increases ↗ | Increases ↗ |

| Infill Density | Increases ↗ | Increases ↗ |

The relationship between the maximum foaming rate, minimum print density, and printing temperature of ASA Aero.

|

Printing Temperature |

Minimun Flow Rate Ratio |

Maximum Volumetric Expansion Ratio |

Maximum Foaming Rate |

Minimum Prints Density |

| 220 °C | ~ 0.93 | ~ 100% | ~ 0% | ~ 0.97 g/cm³ |

| 230 °C | 0.90 | 106% | 6% | 0.92 g/cm³ |

| 240 °C | 0.74 | 128% | 28% | 0.78 g/cm³ |

| 250 °C | 0.60 | 158% | 58% | 0.61 g/cm³ |

| 260 °C | 0.51 | 186% | 86% | 0.52 g/cm³ |

| 270 °C | 0.45 | 211% | 111% | 0.46 g/cm³ |

| 280 °C | 0.44 | 216% | 116% | 0.45 g/cm³ |

Specimen Test: Nozzle Type: 0.4 mm; Printing Speed: 80 mm/s; Model size (L*W*H): 80*10*4 mm³ (the XY direction)

The actual required flow rate ratio and final model density may vary with different models.

Ready for Harsh Environment & Outdoor

Compared with PLA Aero, the overwhelming performance in temperature, water, and UV resistance makes ASA Aero stand out for long-lasting outdoor use and harsh environments.

Matte Finish For Easy Coloring

ASA Aero provides an easy-to-color matte surface texture with better dyeing results as compared with regular ASA.

ASA Hex Code Table

| Color | Hex Code | Display | |

| White | #F5F1DD | ||

| Physical Properties | |

| Density | 0.99 g/cm³ |

| Vicat Softening Temperature | 80 °C |

| Heat Deflection Temperature | 85 °C |

| Melting Temperature | 204 °C |

| Melt Index | 1.56 ± 0.5 g/10 min |

| Mechanical Properties | |

| Tensile Strength | 32 ± 4 MPa |

| Breaking Elongation Rate | 5.1% ± 1.6% |

| Bending Modulus | 1510 ± 120 MPa |

| Bending Strength | 58 ± 6 MPa |

| Impact Strength | 32.0 ± 2.5 kJ/m² |

Available Colors

| Max. Size: | 256x256x256 mm |

| Ship within: | 1 working days |

Material Description

Polyethylene Terephthalate PETG Translucent

PETG Translucent stands out with its exceptional printing characteristics, setting it apart from standard PETG materials. This specially tuned filament minimizes common issues like nozzle sticking, leakage, and clumping during the printing process, providing a hassle-free experience compared to ordinary PETG materials. The filament also exhibits water resistance, UV resistance, and resistance to temperature changes, making it an excellent choice for outdoor applications.

Create with Light, Shadow and a Wide Range of Colors

PETG Translucent offers 8 vibrant colors for you to choose from. Elevate your prints by seamlessly blending different colors and experimenting with various thicknesses of layers and walls.

Durable, Weather-Resistant, and Long-Lasting

PETG Translucent series, designed to withstand the elements with exceptional impact resistance. This filament is not only waterproof but also exhibits impressive resilience under prolonged exposure to UV.

Excellent light transmittance

Optimized for exceptional light transmittance, PETG Translucent provides unmatched levels of translucency.

* Please note that the transparency of the prints may vary depending on factors such as size and structure, as well as printing parameters (including speed, nozzle temperature, and infill density)

PETG Translucent Hex Code Table

| Color | Hex Code | Display |

| Translucent Gray | #8E8E8E | |

| Translucent Light Blue | #61B0FF | |

| Translucent Olive | #748C45 | |

| Translucent Brown | #C9A381 | |

| Translucent Teal | #77EDD7 | |

| Translucent Orange | #FF911A | |

| Translucent Purple | #D6ABFF | |

| Translucent Pink | #F9C1BD |

| Physical Properties | |

| Density | 1.25 g/cm³ |

| Vicat Softening Temperature | 79 °C |

| Heat Deflection Temperature | 74 °C |

| Melting Temperature | 228 °C |

| Melt Index | 11.7 ± 1.5 g/10 min |

| Mechanical Properties | |

| Tensile Strength | 33 ± 4 MPa |

| Breaking Elongation Rate | 8.2 ± 1.3 % |

| Bending Modulus | 1610 ± 130 MPa |

| Bending Strength | 68 ± 3 MPa |

| Impact Strength | 37.4 ± 3.3 kJ/m² |

Available Colors

| Max. Size: | 256x256x256 mm |

| Ship within: | 1 working days |

Material Description

PLA Sparkle

PLA Sparkle is a next-level aesthetic filament that combines strength and sparkle. With metal particles included in its composition, PLA Sparkle adds a special sparkling look to your prints that sets them apart from the rest.

PLA Sparkle Hex Code Table

| Color | Hex Code | Display |

| Classic Gold Sparkle | #CEA629 | |

| Slate Gray Sparkle | #8E9089 | |

| Crimson Red Sparkle | #792B36 | |

| Royal Purple Sparkle | #483D8B | |

| Alpine Green Sparkle | #3F5443 | |

| Onyx Black Sparkle | #2D2B28 |

| Physical Properties | |

| Density | 1.26 g/cm³ |

| Vicat Softening Temperature | 57 °C |

| Heat Deflection Temperature | 55 °C |

| Melting Temperature | 156 °C |

| Melt Index | 34.2 ± 3.3 g/10 min |

| Mechanical Properties | |

| Tensile Strength | 33 ± 3 MPa |

| Breaking Elongation Rate | 11.7 ± 0.7 % |

| Bending Modulus | 2310 ± 140 MPa |

| Bending Strength | 63 ± 4 MPa |

| Impact Strength | 66.5 ± 3.6 kJ/m² |

Available Colors

| Max. Size: | 256x256x256 mm |

| Ship within: | 1 working days |

Material Description

PLA Aero

PLA Aero achieves low density and light weight by foaming at high temperatures during printing and creating small holes inside the prints. It's the perfect choice for light-weight and energy-saving prints, including unmanned aerial vehicles (UAVs), aerodynamic models, and gliders.

Low Density and Light Weight

PLA Aero has almost the same filament density as regular PLA, while the prints density is only 50% to 80%.

* When printing models of the same volume, PLA Aero is about half the weight of PLA Basic.

Controllable Model Density

Achieve lower density of the prints by increasing printing temperature and lowering flow rate.

* The average density of prints will vary with changes in parameters such as actual printing temperature, flow rate ratio, printing speed, model size, wall thickness and infill density.

| Parameter Setting | Average Density | |

| Printing Temperature | Increases ↗ | Decreases ↘ |

| Printing Speed | Increases ↗ | Stable or Increases ↗ |

| Flow Rate Ratio | Increases ↗ | Increases ↗ |

| Model Size | Increases ↗ | Decreases ↘ |

| Wall Thickness(Wall loops) | Increases ↗ | Increases ↗ |

| Infill Density | Increases ↗ | Increases ↗ |

The relationship between the maximum foaming rate, minimum print density, and printing temperature of PLA Aero.

|

Printing Temperature |

Minimum Flow Rate Ratio |

Maximum Volumetric Expansion Ratio |

Maximum Foaming Rate |

Minimum Prints Density |

| 190 °C | ~ 0.95 | ~ 100% | ~ 0% | ~ 1.17 g/cm³ |

| 200 °C | 0.89 | 110% | 10% | 1.06 g/cm³ |

| 210 °C | 0.85 | 115% | 15% | 1.02 g/cm³ |

| 220 °C | 0.76 | 129% | 29% | 0.91 g/cm³ |

| 230 °C | 0.62 | 158% | 58% | 0.74 g/cm³ |

| 240 °C | 0.45 | 217% | 117% | 0.54 g/cm³ |

| 250 °C | 0.38 | 258% | 158% | 0.45 g/cm³ |

| 260 °C | 0.35 | 280% | 180% | 0.42 g/cm³ |

| 270 °C | 0.37 | 265% | 165% | 0.44 g/cm³ |

Tough with Good Impact Resistance

Compared to pre-foaming Wood PLA, PLA Aero and its prints are tougher and more resistant to impact, collision, and falling.

Matte Finish For Easy Coloring

PLA Aero provides an easy-to-color matte surface texture with better dyeing results as compared to PLA Basic.

| Physical Properties | |

| Density | 1.21 g/cm³ |

| Vicat Softening Temperature | 54 °C |

| Heat Deflection Temperature | 53 °C |

| Melting Temperature | 153 °C |

| Melt Index | 7.7 ± 0.6 g/10 min |

| Mechanical Properties | |

| Tensile Strength | 24 ± 2 MPa |

| Breaking Elongation Rate | 2.6 ± 0.7 % |

| Bending Modulus | 1690 ± 120 MPa |

| Bending Strength | 45 ± 4 MPa |

| Impact Strength | 28.8 ± 1.3 kJ/m² |

Available Colors

| Max. Size: | 256x256x256 mm |

| Ship within: | 1 working days |

Material Description

Carbon Fiber Reinforced PA6 (Nylon 6)

PA6-CF is a carbon fiber reinforced PA6 (Nylon 6) filament. The carbon fiber reinforcement provides significantly high stiffness and strength properties in dry environments and maintains exceptional heat resistance and impact resistance. Similar to other CF Filaments, these outstanding mechanical properties make it an ideal choice for printing fixtures, clamps, automotive and mechanical components and various structural and engineering parts that used in dry environments.

Superior Strength and Stiffness

PA6-CF keeps superior stiffness and strength properties in dry environments, it is perfect for printing load-bearing structural components.

| Normal PA-CF | PA6-CF | Improved % | |

| Strength (Bending Strength - XY, dry state) | 128 MPa | 151 MPa | 18% |

| Stiffness (Bending Modulus - XY, dry state) | 4420 MPa | 5460 MPa | 24% |

Impact & Vibration Resistance

PA6-CF offers excellent impact resistance, ensuring effective vibration resistance for your prints. It is commonly used to print models that need to withstand impact, collision, and vibration.

* The prints of PA6-CF will be tougher after putting in humid environment more than 1 day.

Exceptional Thermal Resistance

| Filament | PLA Basic | PETG Basic | ABS | ASA | PC | PA6-CF | PAHT-CF | PET-CF |

| Heat Deflection Temperature / ℃ (0.45 MPa) | 57 ℃ | 69 ℃ | 87 ℃ | 100 ℃ | 117 ℃ | 186 ℃ | 194 ℃ | 205 ℃ |

| Physical Properties | |

| Density | 1.09 g/cm³ |

| Vicat Softening Temperature | 212 °C |

| Heat Deflection Temperature | 186 °C |

| Melting Temperature | 223 °C |

| Melt Index | 6.8 ± 0.6 g/10 min |

| Mechanical Properties | |

| Tensile Strength | 102 ± 7 MPa |

| Breaking Elongation Rate | 5.8 ± 1.6 % |

| Bending Modulus | 5460 ± 280 MPa |

| Bending Strength | 151 ± 8 MPa |

| Impact Strength | 40.3 ± 2.5 kJ/m² |

Available Colors

| Max. Size: | 256x256x256 mm |

| Ship within: | 1 working days |

Material Description

PLA Galaxy

Galaxy -- where innovation meets elegance. Experience a new dimension of printing with filament infused with glass microsphere additives. This unique blend creates mesmerizing visual effects, offering dynamic reflections and a glossy, smooth finish. Elevate your prints to new heights as they gleam with unparalleled brilliance from every angle, all while maintaining the ease of printing and exceptional strength and toughness you expect from PLA Basic.

Appealing from Every Angle

PLA Galaxy's glass microsphere additives create unique light effects, offering dynamic reflections from various perspectives.

Sleek Glossy Finish

Enriched with glass microsphere additives, PLA Galaxy ensures a clear, seamlessly smooth surface texture, enhancing your prints with a captivating fluidity that is both dynamic and refined.

PLA Galaxy Hex Code Table

| Color | Hex Code | Display | |

| Brown (Brown base with gold shimmer) | #684A43 | ||

| Green (Green base with gold shimmer) | #3B665E | ||

| Nebulae (Deep blue base with green shimmer) | #424379 | ||

| Purple (Purple base with blue shimmer) | #594177 | ||

| Physical Properties | |

| Density | 1.19 g/cm³ |

| Vicat Softening Temperature | 56 °C |

| Heat Deflection Temperature | 52 °C |

| Melting Temperature | 156 °C |

| Melt Index | 11.0 ± 1.7 g/10 min |

| Mechanical Properties | |

| Tensile Strength | 26 ± 3 MPa |

| Breaking Elongation Rate | 9.3 ± 1.1 % |

| Bending Modulus | 2200 ± 120 MPa |

| Bending Strength | 58 ± 3 MPa |

| Impact Strength | 55.4 ± 3.7 kJ/m² |

Available Colors

| Max. Size: | 256x256x256 mm |

| Ship within: | 1 working days |

Material Description

Carbon Fiber Reinforced PET

PET-CF is a blend of tough PET and carbon fiber. Carbon fiber improves hardness and mechanical strength, while still help maintain the low warping and shrinkage of ordinary PET. PET-CF has excellent high temperature resistance and a soft glow appearance. Its excellent strength, heat resistance, dimensional stability and low moisture absorption make PET-CF an ideal choice for load-bearing structures or prints used in high temperature and humid environments.

Low moisture absorption

In saturated water absorption conditions, the strength and stiffness of PET-CF have small losses, making it suitable for prints used in high humidity environments.

High dimensional stability

Due to the creep and warping resistance of PET-CF, prints can achieve excellent matching accuracy.

Frequently Asked Questions

What is the difference between PET-CF and PETG-CF?

The primary difference between PET-CF and PETG-CF lies in their base material. PETG-CF is a reinforced material made by adding carbon fiber to glycol-modified polyethylene terephthalate (PETG), while PET-CF is to polyethylene terephthalate (PET). The key difference 'G' in PETG stands for glycol. PETG is a glycol-modified version of PET that contains small amounts of glycol as a co-monomer. The addition of glycol to PETG reduces its crystallinity and makes it more transparent. However, it also reduces its strength and stiffness.

The difference in application between PETG-CF and PET-CF?

PETG-CF is a versatile basic material that is suitable for printing everyday items, such as bent, folded, and movable parts, due to its excellent toughness and ease of printing. PET-CF, in contrast, contains a greater amount of carbon fiber and is significantly stronger and more temperature resistant compared to PETG-CF. PET-CF is a professional-grade engineering material that is suitable for use in more complex and demanding environments.

What is PET-CF used for?

Due to its dimensional stability and lower water absorption rate, PET-CF is a better choice than nylon for printing functional parts used in high humidity environments. Also, its high-temperature resistance and low warping make it suitable for printing mechanical assembly parts, such as automotive accessories and fixtures.

| Physical Properties | |

| Density | 1.29 g/cm³ |

| Vicat Softening Temperature | 226 °C |

| Heat Deflection Temperature | 205 °C |

| Melting Temperature | 250 °C |

| Melt Index | 25.3 ± 2.5 g/10 min |

| Mechanical Properties | |

| Tensile Strength | 74 ± 6 MPa |

| Breaking Elongation Rate | 4.5 ± 1.2 % |

| Bending Modulus | 5320 ± 270 MPa |

| Bending Strength | 131 ± 6 MPa |

| Impact Strength | 36.0 ± 2.7 kJ/m² |

Available Colors

| Max. Size: | 256x256x256 mm |

| Ship within: | 1 working days |

Material Description

PLA Silk

PLA Silk offers a silk-like and high-glossy that adds a luxury appearance to your prints while retaining PLA's ease of use. Different with other silk filaments, PLA Silk was toughened and demonstrates greater resistance to breakage when using AMS printing. It's ideal for decorations, artistic projects, and 3D character models or any parts where you want it shinier.

Silk-like appearance with ultra-high gloss

PLA Silk brings a silk-like appearance and long-lasting high gloss to your 3D prints, transforming models into stunning art.

Silky appearance shining glow

Display of Silk Prints

PLA Silk is ideal for decorations, artistic projects, and 3D character models or any parts where you want it shinier.

PLA Silk Hex Code Table

| Color | Hex Code | Display |

| White | #FFFFFF | |

| Silver | #EAECEB | |

| Pink | #EEB1C1 | |

| Green | #4CE4A0 | |

| Gold | #E5B03D | |

| Blue | #147BD1 | |

| Purple | #854CE4 | |

| Copper | #5E4B3C |

| Physical Properties | |

| Density | 1.32 g/cm³ |

| Vicat Softening Temperature | 56 °C |

| Heat Deflection Temperature | 53 °C |

| Melting Temperature | 152 °C |

| Melt Index | 20.5 ± 1.2 g/10 min |

| Mechanical Properties | |

| Tensile Strength | 27 ± 4 MPa |

| Breaking Elongation Rate | 3.5 ± 0.6 % |

| Bending Modulus | 2370 ± 150 MPa |

| Bending Strength | 66 ± 4 MPa |

| Impact Strength | 24.5 ± 1.7 kJ/m² |

Available Colors

| Max. Size: | 256x256x256 mm |

| Ship within: | 1 working days |

Material Description

Carbon Fiber Reinforced High Temperature Nylon

Key Features

- Low Moisture Absorption

- Exceptional Mechanical Properties & Layer Adhesion

- High Tensile Strength

PAHT-CF is a composite of PA12 and carbon fiber. Inheriting the advantages of low water absorption from PA12 and high-performance carbon fiber, PAHT-CF offers excellent mechanical and thermal properties that can be maintained well even when the prints get wet. Higher Z adhesion layers and flexibility make it ideal for creating engineering parts such as functional prototypes, machining fixtures, injection molds, jigs, and low-volume production parts.

Low water absorption

With a 50% lower water absorption rate compared to normal PA-CF, PAHT-CF maintains excellent mechanical properties and dimensional stability even when exposed to high humidity.

Mechanical Properties Comparison

| Normal PA-CF | PAHT-CF | |

| Saturated Water Absorption Rate/% ( 25 °C, 55% RH ) | 1.70 | 0.88 |

| Bending Strength - XY/MPa (Dry) | 128 | 125 |

| Bending Strength - XY/MPa (Wet) | 76 | 115 |

| Bending Strength - Z/MPa (Dry) | 48 | 61 |

| Bending Strength - Z/MPa (Wet) | 34 | 49 |

| Bending Modulus - XY/MPa (Dry) | 4420 | 4230 |

| Bending Modulus - XY/MPa (Wet) | 2210 | 3640 |

| Bending Modulus - Z/MPa (Dry) | 1470 | 1820 |

| Bending Modulus - Z/MPa (Wet) | 770 | 1480 |

| Decline rate of mechanical properties after absorbing water/% | 40%-45% | 12%-18% |

Exceptional Z-bonding

PAHT-CF shows much higher adhesion in Z layers compared to normal PA-CF, bringing it the ability to withstand high levels of impact or stress without breaking or deforming.

Z-layer Performance

| Normal PA-CF | PAHT-CF | Improved % | |

| Bending Strength - Z/MPa | 48 | 61 | 27% |

| Bending Modulus - Z/MPa | 1470 | 1820 | 24% |

| Impact Strength - Z/(kJ/m²) | 5.7 | 13.3 | 133% |

High tensile strength

PAHT-CF is designed to meet the demands of various industrial and engineering applications where high strength and durability are required.

Designed for high-temperature resistance

The heat deflection temperature of PAHT-CF is up to 194℃ (0.45MPa)*, making it useful in applications where the printed parts may be exposed to high temperatures without deforming or losing their strength.

*The long-term temperature resistance is related to the structure and usage scenario of the model itself.

| Physical Properties | |

| Density | 1.06 g/cm³ |

| Vicat Softening Temperature | 220 °C |

| Heat Deflection Temperature | 194 °C |

| Melting Temperature | 225 °C |

| Melt Index | 14.4 ± 2.0 g/10 min |

| Mechanical Properties | |

| Tensile Strength | 92 ± 7 MPa |

| Breaking Elongation Rate | 8.4 ± 1.8 % |

| Bending Modulus | 4230 ± 210 MPa |

| Bending Strength | 125 ± 7 MPa |

| Impact Strength | 57.5 ± 3.4 kJ/m² |

Available Colors

| Max. Size: | 256x256x256 mm |

| Ship within: | 1 working days |

Material Description

Soft Bicolor Gradient Appearance

The soft transition between two colors creates a vibrant and stunning visual effect on printed models.

Display of Gradient Prints

Gradient colors make it ideal for printing pretty toys or decorations.

8 ~ 10 Meters Gradient Length

Smaller models with less filament consumption will have a less noticeable gradient looks, while larger models with more filament consumption comes with a noticeable gradient looks.

Excellent Layer Adhesion

The gradient filament retains similar performance to PLA Basic while providing even stronger layer adhesion and toughness, reducing the risk of printed parts breaking.

Z-layer Performance

| Layer Adhesion (Impact Strength - Z) | Improved % | |

| Normal Matte PLA | 6.6 kJ/m² | 261% |

| Bambu PLA Basic Gradient | 23.8 kJ/m² | |

| Specimens:20*2*80 mm³ | ||

PLA Basic Gradient Hex Code Table

| Color | Hex Code | Display |

| Arctic Whisper | #9CDBD9; #FFFFF | |

| Solar Breeze | #E94B3C; #FFFFFF | |

| Ocean to Meadow | #307FE2; #54FF9B |

| Physical Properties | |

| Density | 1.24 g/cm³ |

| Vicat Softening Temperature | 57 °C |

| Heat Deflection Temperature | 57 °C |

| Melting Temperature | 160 °C |

| Melt Index | 42.4 ± 3.5 g/10 min |

| Mechanical Properties | |

| Tensile Strength | 36 ± 2 MPa |

| Breaking Elongation Rate | 15.2 ± 0.5 % |

| Bending Modulus | 2270 ± 60 MPa |

| Bending Strength | 73 ± 3 MPa |

| Impact Strength | 61.2 ± 2.8 kJ/m² |

Available Colors

| Max. Size: | 256x256x256 mm |

| Ship within: | 1 working days |

Material Description

PA6-GF - Glass Fiber Reinforced Nylon

PA6-GF, also known as Nylon 6 with Glass Fiber, stands at the forefront of high-performance engineering plastics. Engineered to deliver exceptional strength, durability, dimensional stability. The PA6-GF is also more cost effective when compared to other top tier engineering filaments.

Built to Last

PA6-GF is exceptionally strong and durable due to reinforced glass fibers, making it the perfect choice for prints that need to withstand heavy use and resist bending or breaking.

* Note: The printed part achieves better toughness after exposure to moisture.

Dimensional Stability

PA6-GF boasts unparalleled dimensional stability thanks to its glass fiber reinforcement, minimizing warping in comparison to standard PA filaments. Print with precise dimensions, even in the most intricate geometries.

Exceptional Thermal Properties

PA6-GF boasts a high heat deflection temperature and superior dimensional stability, enabling it to retain its mechanical properties even under elevated temperatures. This makes it ideal for demanding industrial and automotive applications.

| Filament Type | PLA Basic | ABS | Normal PA | PC | PA6-GF | PA6-CF | PAHT-CF | PET-CF |

| Heat Deflection Temperature / ℃ (0.45 MPa) | 57 ℃ | 87 ℃ | 89 ℃ | 117 ℃ | 182 ℃ | 186 ℃ | 194 ℃ | 205 ℃ |

Chemical Resistance

PA6-GF offers excellent resistance to chemicals, oils, and many kinds of solvents, ensuring long-term performance in challenging environments.

Smooth Surface and More Colors

Bambu PA6-GF filaments are compatible with the Bambu AMS system, ready to print in multi-color. The special surface texture also blurs the layer lines, providing a smooth surface quality.

PA6-GF Hex Code Table

| Color | Hex Code | Display |

| White | #EAEAE4 | |

| Yellow | #FFCE00 | |

| Lime | #C5ED48 | |

| Blue | #75AED8 | |

| Orange | #FF4800 | |

| Brown | #5B492F | |

| Gray | #353533 | |

| Black | #000000 |

| Physical Properties | |

| Density | 1.14 g/cm³ |

| Vicat Softening Temperature | 210 °C |

| Heat Deflection Temperature | 182 °C |

| Melting Temperature | 219 °C |

| Melt Index | 9.0 ± 0.8 g/10 min |

| Mechanical Properties | |

| Tensile Strength | 75 ± 6 MPa |

| Breaking Elongation Rate | 3.9 ± 0.8 % |

| Bending Modulus | 3670 ± 140 MPa |

| Bending Strength | 120 ± 6 MPa |

| Impact Strength | 27.2 ± 2.2 kJ/m² |

Available Colors

| Max. Size: | 256x256x256 mm |

| Ship within: | 1 working days |

Material Description

PLA Silk Dual Color

PLA Silk Dual-Color filament is crafted from two individual silk colors seamlessly blended into a single strand. Retaining its silky texture and high-gloss features, this filament transitions between two colors, creating a natural and smooth gradient. You can easily change the visible color by rotating the color-blending filament to different orientations. Ideal for printing aesthetic parts and decorative objects. Elevate your creations with the smooth and captivating allure of PLA Silk Dual-Color filament.

Captivating Silk Appearance with Dynamic Color Transformations

Crafted from two individual colors seamlessly merged into a single filament strand, this filament promises a mesmerizing silk appearance. Simply rotate the model to see different color effects, revealing enchanting color fusions that spark your creativity.

PLA Silk Dual Color Hex Code Table

| Color | Hex Code | Display | |

| Velvet Eclipse (Black-Red) | #000000; #A34342 | ||

| Midnight Blaze (Blue-Red) | #0047BB; #7D1B49 | ||

| Neon City (Blue-Magenta) | #0047BB; #BB22A3 | ||

| Gilded Rose (Pink-Gold) | #FF9425; #FCA2BF | ||

| Blue Hawaii (Blue-Green) | #60A4E8; #4CE4A0 | ||

| Physical Properties | |

| Density | 1.32 g/cm³ |

| Vicat Softening Temperature | 56 °C |

| Heat Deflection Temperature | 53 °C |

| Melting Temperature | 152 °C |

| Melt Index | 20.5 ± 1.2 g/10 min |

| Mechanical Properties | |

| Tensile Strength | 27 ± 4 MPa |

| Breaking Elongation Rate | 3.5 ± 0.6 % |

| Bending Modulus | 2370 ± 150 MPa |

| Bending Strength | 66 ± 4 MPa |

| Impact Strength | 24.5 ± 1.7 kJ/m² |

Available Colors

| Max. Size: | 256x256x256 mm |

| Ship within: | 1 working days |

Material Description

Premium Carbon Fiber Reinforced Nylon (PPA-CF)

PPA-CF, a premium fiber-reinforced nylon, delivers industrial-grade printing quality with precise 1:1 reproduction. Renowned for its exceptional mechanical properties and reliable performance in humid or high-temperature environments, Bambu PPA-CF is ideal for engineering applications, from mechanical prototypes to automotive components. Additionally, its broad printer compatibility sets a new standard for professional engineering filaments. Experience the power of PPA-CF and bring your designs to life!

Metal-Like Strength

PPA-CF offers strength approaching metal levels, being 48% stronger and 102% stiffer than normal PA6-CF. This filament excels in mechanical properties, making it ideal for high-performance engineering applications. Perfect for repairs, it can effectively replace automotive and industrial parts with exceptional durability and reliability.

| Filament | Normal PA6-CF | PA6-CF | PAHT-CF | PPA-CF |

| Stiffness (Bending Modulus - XY, Dry State) | 4870 MPa | 5460 MPa | 4230 MPa | 9860 MPa |

| Strength (Bending Strength - XY, Dry State) | 141 MPa | 151 MPa | 125 MPa | 208 MPa |

Industrial-Grade Precision

Achieve industrial-grade precision with PPA-CF. Its superior dimensional stability ensures that your high-precision prototypes match your design drawings exactly, without warping or deformation. Rely on PPA-CF for the accuracy you need in every project.

Stable Performance in Humid Conditions

PPA-CF supports long-term, stable use in humid environments, even underwater. With a moisture absorption rate 66% lower than normal PA6-CF, it maintains its stiffness and thermal properties over time. Whether printing propellers, customizing surfboards, or any other water-resistant application, PPA-CF delivers reliable performance.

Unmatched Performance Under High Temperatures

PPA-CF boasts unmatched heat resistance, capable of withstanding prolonged exposure to temperatures up to 227°C without compromising its structural integrity or performance. This filament remains reliable and robust in extreme environments, making it perfect for industrial, mechanical, or automotive parts that must tolerate ultra-high temperatures.

| Physical Properties | |

| Density | 1.25 g/cm³ |

| Vicat Softening Temperature | 232 °C |

| Heat Deflection Temperature | 227 °C |

| Melting Temperature | 258 °C |

| Melt Index | 8.4 ± 0.7 g/10 min |

| Mechanical Properties | |

| Tensile Strength | 168 ± 4 MPa |

| Breaking Elongation Rate | 3.2 ± 0.4 % |

| Bending Modulus | 9860 ± 480 MPa |

| Bending Strength | 208 ± 6 MPa |

| Impact Strength | 41.7 ± 2.8 kJ/m² |

Available Colors

| Max. Size: | 256x256x256 mm |

| Ship within: | 1 working days |

COPYRIGHT © 2025 PLANFAB.EU. ALL RIGHTS RESERVED.

Powered by 3D ABAX.