- PLA + CF - Hyper Speed Large -( 12 x faster )

- Nylon

- Hyper-Speed PLA-( 12 x faster )

- PA12 Nylon

- PLA - Hyper Speed Large -( 12 x faster )

- PETG - Hyper Speed - Larger Format ( 12 x faster )

- ABS Hyper-Speed - Larger Format -( 12 x faster )

- ASA

- TPU - 70A

Material Description

Polylactic acid, also known as PLA, is a thermoplastic monomer derived from renewable, organic sources such as corn starch or sugar cane. Using biomass resources makes PLA production different from most plastics, which are produced using fossil fuels through the distillation and polymerization of petroleum.

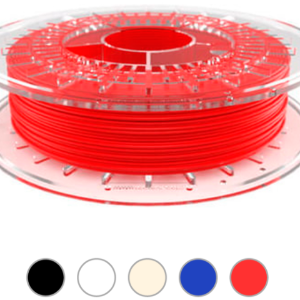

Available Colors

| Max. Size: | 300x300x300 mm |

| Ship within: | 3 working days |

Material Description

This filament is commonly used for semi-flexible and mechanical parts since its chemical, wear and UV resistance is higher compared with basic 3D printing plastics. The downside of nylon filament is its tricky behavior when used with some desktop FDM machines.

If printed thin enough, it can provide decent flexibility while maintaining toughness. Nylon's low coefficient of friction also means it's well suited for making functional moving parts. Therefore, nylon is often used for making functional prototypes, living hinges, gears, and similar end-use parts.

How strong are nylon 3D prints?

Also remember to print in an enclosed environment for best results. Nylon is a great material for making structural parts. Compared to ABS with a tensile strength of 4,700 psi, nylon's estimated tensile strength of 7,000 psi is head and shoulders above ABS

Available Colors

| Max. Size: | 300x300x300 mm |

| Ship within: | 3 working days |

Material Description

Polylactic acid, also known as PLA, is a thermoplastic monomer derived from renewable, organic sources such as corn starch or sugar cane. Using biomass resources makes PLA production different from most plastics, which are produced using fossil fuels through the distillation and polymerization of petroleum.

Available Colors

| Max. Size: | 200x200x250 mm |

| Ship within: | 5 working days |

Material Description

PA12, also known as Nylon 12, is a versatile and widely used thermoplastic material with a range of applications across various industries. It belongs to the polyamide (PA) family of plastics and is known for its exceptional properties. Here's a detailed description of PA12 Nylon:

Chemical Composition: PA12 is a synthetic polymer made from the polymerization of laurolactam monomers. Its molecular structure consists of a repeating unit of amide groups, which gives it its characteristic properties.

Physical Properties:

-

High Strength: PA12 Nylon is renowned for its excellent tensile strength, making it a robust and durable material. It can withstand significant mechanical stresses and loads.

-

Flexibility: Despite its strength, PA12 Nylon is relatively flexible, allowing it to endure bending and twisting without breaking. This property makes it suitable for applications that require both strength and flexibility.

-

Low Friction: PA12 has a low coefficient of friction, making it an excellent choice for components that require smooth movement or sliding, such as bearings and gears.

-

Chemical Resistance: It exhibits good resistance to many chemicals, oils, and solvents, making it suitable for use in harsh environments.

-

Low Moisture Absorption: PA12 Nylon has relatively low moisture absorption compared to some other nylon materials. This property helps maintain its mechanical properties in humid conditions.

Thermal Properties:

-

High Melting Point: PA12 has a relatively high melting point, typically around 180-190°C (356-374°F), which allows it to maintain its structural integrity at elevated temperatures.

-

Thermal Stability: It exhibits good thermal stability, making it suitable for applications where it may be exposed to heat over extended periods.

Other Notable Properties:

-

Electrical Insulation: PA12 is an excellent electrical insulator, which makes it suitable for various electrical and electronic applications.

-

Lightweight: It has a low density, making it a lightweight material, which is advantageous in applications where weight is a consideration.

Applications:

PA12 Nylon is used in a wide range of applications, including:

-

Manufacturing: It's used for producing various industrial components, such as gears, bushings, rollers, and pulleys, due to its excellent mechanical properties.

-

Automotive: PA12 is found in automotive components like fuel lines, air intake manifolds, and cable sheathing, thanks to its durability and resistance to automotive fluids.

-

Medical: It's used in medical devices and equipment because of its biocompatibility and resistance to sterilization methods.

-

Consumer Goods: PA12 is used in the production of everyday items like sports equipment, zippers, and luggage due to its strength and flexibility.

-

Aerospace: In aerospace applications, PA12 is used for lightweight structural components and parts that require high strength.

-

3D Printing: PA12 is a popular material for 3D printing, particularly in selective laser sintering (SLS) and Multi Jet Fusion (MJF) technologies, where it can create durable and functional prototypes and end-use parts.

Available Colors

| Max. Size: | 250x250x350 mm |

| Ship within: | 7 working days |

Material Description

Polylactic acid, also known as PLA, is a thermoplastic monomer derived from renewable, organic sources such as corn starch or sugar cane. Using biomass resources makes PLA production different from most plastics, which are produced using fossil fuels through the distillation and polymerization of petroleum.

Available Colors

| Max. Size: | 300x300x300 mm |

| Ship within: | 3 working days |

Material Description

PETG is a Glycol Modified version of Polyethylene Terephthalate (PET), which is commonly used to manufacture water bottles. It is a semi-rigid material with good impact resistance, but it has a slightly softer surface which makes it prone to wear.

Advantages

- Excellent layer adhesion.

- Warp resistance.

- Reduced shrinkage.

- Higher density.

- Chemical resistance to both acidic and alkali compounds.

- Flexible printing on glass, acrylic, glass, blue tape and polyimide tape.

- Odorlessness during printing.

REQUEST A SAMPLE PART

Available Colors

| Max. Size: | 300x300x300 mm |

| Ship within: | 3 working days |

Material Description

Hyper Speed ABS

The ABS thermoplastic composition of Hyper Speed material is subjected to a meticulously controlled heating process. This transformative procedure guarantees the seamless fusion of each layer, establishing a robust and flawless base for your design endeavors.

Cost-Effective Excellence Attain unmatched print quality without being burdened by financial limitations, positioning Hyper Speed ABS as a beacon of cost-effective innovation. Dominant Presence: Hyper Speed ABS boasts an impressive 80% market share in the world of 3D printed items, a testament to its unparalleled versatility.

Testing Method: ISO 1183, GB/T 1033

Available Colors

| Max. Size: | 300x300x300 mm |

| Ship within: | 3 working days |

Material Description

The ASA (Acrylonitrile Styrene Acrylate) is a thermoplastic that combines the mechanical robustness, the resistance to UV rays, the resistance to water with a great surface finish, which makes the filament ASA suitable to make final pieces in 3D for machinery or prototypes Durable for outdoor use in the open

Available Colors

| Max. Size: | 350x350x410 mm |

| Ship within: | 7 working days |

Material Description

Filaflex UltraSoft 70A is one of the most elastic and softest filaments on the market, reaching a 900% stretch until breaking. The Filaflex UltraSoft filament is a TPE filament (Thermoplastic Elastomer) with a polyurethane base and certain additives.

The Filaflex Ultrasoft 70A filament has an even higher elasticity and smoothness than the Filaflex 82A (Filaflex), with a Shore 70A hardness and an abrasion resistance of 45mm3, being one of the most elastic and soft filaments on the market. Like the Filaflex, the Filaflex Ultrasoft 70A is resistant to solvents, acetone and fuels, but with lower tensile strength and lower softening temperature. The Filaflex UltraSoft 70A has good bonding properties with other types of materials used in the field of 3D printing, such as PLA, ABS, HiPS and some Nylons, resulting in composite pieces with different properties and hardness. Thanks to all the qualities mentioned above, this material has an infinity of applications in all types of fields

FilaFlex UltraSoft is non-toxic, but not approved for medical or nutritional use. This material doesn't emit odors, is totally odorless and does not produce toxic gases. Due to its high elasticity, it is a complex material to use, since, in certain types of extruders, it's likely to wrap around the pinion of the extruder motor or directly bend the filament already before entering the HotEnd, something that occurs if a Bowden drive system is used. Therefore, this material is recommended only for advanced users and with 3D printers with the Recreus Extruder v3 extruder or with an extruder prepared to print elastic filaments (Should always be direct drive, never bowden). The "Recreus Extruder v3" is a direct-drive extruder extruder with high quality components created by the manufacturer of the Filaflex UltraSoft 70A, to be able to use this and other flexible materials without any problems and at high speeds compared to the rest of extruders on the market . Another extruder compatible with this material, but not recommended by the manufacturer, is the E3D Titan Aero.

Available Colors

| Max. Size: | 300x300x300 mm |

| Ship within: | 3 working days |

Powered by Mitchell and Son Additive Manufacturing Ltd