- FDM - Ninja Flex (TPU)

- FDM - ABS

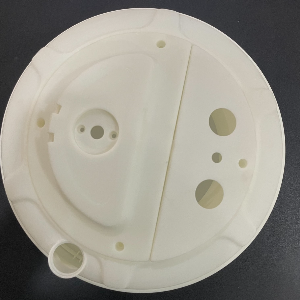

- SLA - ZR300 (ABS Tough)

- SLA - Accura ClerVue (Transparent)

- FDM - PLA

- SLS - Nylon P12

- DMLS - AlSi10Mg

- DMLS - In718-0405

- DMLS - Maraging steel M300

- DMLS - SS316L

- FDM - PETG

- FDM - Flex PLA (TPU)

- SLS - Nylon Glass Filled (PA 3200 GF)

Material Description

- Shore Hardness = 85A

- Truly flexible

- 660% elongation allows for repeated movement and impact without wear or cracking

- Polyurethane composition allows for excellent vibration reduction

- Proprietary low-friction exterior allows for smooth feeding

- Abrasion resistance 20% better than ABS and 68% better than PLA

- Consistent diameter and material properties providing reliable, high-quality prints

- Chemical resistance to many materials.

- REACH and RoHS 3 (EU 2015/863)

Available Colors

| Max. Size: | 210x210x303 mm |

| Ship within: | 2 working days |

Material Description

ABS is both more heat-resistant and more flexible than PLA. However, ABS can be harder to print, warping in odd ways particularly for large, thin structures. However, ABS is one the most popular materials for both production and prototyping and therefore a popular material for hobby applications, Mock ups ,Models, etc.

Available Colors

| Max. Size: | 290x290x380 mm |

| Ship within: | 3 working days |

Material Description

ZR300 is a SLA resin which has high elongation and excellent flexibility that can be produced rigidity, tough, water-resistant and low shrinkage parts.

SLA parts can be painted with Any Color.

- Low Batch Manufacturing

- Form Fit check

- Design Mockups

- Best Suitable for RPT

- High accuracy with Smooth Surface finish

Available Colors

| Max. Size: | 600x600x450 mm |

| Ship within: | 2 working days |

Material Description

Utilized in a variety of demanding applications, 3D Systems Accura ClearVue for SLA is the most clear and colorless 3D printing material on the market. Formulated for ease-of-processing, exceptional detail and smooth surface finish, strength, durability and moisture resistance, it simulates the properties and appearance of Polycarbonate and ABS.

- Lighting and lenses

- Fluid flow visualization models

- Transparent assemblies

- Packaging/bottles

- General purpose prototyping

- Medical models and devices (USP Class VI capable)

- Master patterns for RTV molding

- QuickCastTM patterns for investment casting

- Prototypes of conformal cooling molds

- Snap fits and complex assemblies

Available Colors

| Max. Size: | 600x600x450 mm |

| Ship within: | 2 working days |

Material Description

PLA is a common thermoplastic polymer derived from natural sources such as corn starch or sugar cane — in contrast to many other thermoplastics which are produced from non-renewable sources such as petroleum. From automotive to food packaging, a range of industries are using PLA to produce 3D printed products.

Advantages of PLA include:

- Low printing temperature: PLA has a relatively low printing temperature compared to other thermoplastics (e.g. for PLA an ideal printing temperature starts from around 180°C, while ABS this is around 250°C). This means that PLA is less likely to warp and clog the nozzle during the printing process. Also, compared to ABS and other thermoplastics with higher melting temperatures, PLA typically produces better surface details and sharper features.

- Ease of use: PLA is one of the easiest material filaments to 3D print with. The material easily adheres to a variety of surfaces and doesn’t require a heated print bed which, again, adds to its ease of use. Unlike ABS, PLA also does not emit smelly fumes when printed.

- Variety of colour and blending options: PLA is easily pigmented and comes in a diverse range of colours and blends. The material can also be mixed with wood, carbon and even metal, whilst pigments can also be added t to get luminescent or glittery filaments. This makes the choice of PLA blends virtually endless.

- Easy post-processing: PLA prints can be easily sanded, polished and painted, allowing for an improved surface finish with relatively little effort. You can also drill, mill and glue PLA parts — but be careful not to melt the part. To prevent melting your PLA part, simply keep the process slow and the tools cold (you can achieve this with water, WD-40 or proper cutting fluid).

- Biodegradable: PLA is an eco-friendly material, as it’s biodegradable, non-toxic and also requires less energy to 3D print and emits fewer greenhouse gases than petroleum-based materials. Compared to petroleum-based thermoplastics, which take thousands of years to break down, PLA parts can typically (naturally) break down within a few years, or even months.

Available Colors

| Max. Size: | 210x210x200 mm |

| Ship within: | 3 working days |

Material Description

• Excellent mechanical properties

• Outstanding surface smoothness

• Stable dimensional and mechanical properties over time

• Exceptional recyclability

• Very high part density

Available Colors

| Max. Size: | 380x330x460 mm |

| Ship within: | 5 working days |

Material Description

Material properties

• Low density (good for light weight components)

• High specific strength (strength to mass ratio)

• High thermal conductivity

• Very high electrical conductivity

• Responds well to post process finishing

Applications

• Automotive

• Aerospace and defence

• Electronics cooling

• Consumer goods

Available Colors

| Max. Size: | 210x210x320 mm |

| Ship within: | 5 working days |

Material Description

Material properties

• Retains strength up to 650 °C

• High creep resistance

• High corrosion resistance

• Solidification properties suit additive manufacture

Applications

• Aerospace and defence

• Gas turbine blades

• Exhaust manifolds

• Rocket motors

• Heat exchangers

• Nuclear

Available Colors

| Max. Size: | 210x210x320 mm |

| Ship within: | 5 working days |

Material Description

Material properties

• High strength

• High hardness

• High fatigue strength

• Good machinability

Applications

• Tooling inserts

• Mould and die

• High strength components

Available Colors

| Max. Size: | 210x210x320 mm |

| Ship within: | 5 working days |

Material Description

Material properties

• High hardness and toughness

• High corrosion resistance

• High machine-ability

• Can be highly polished

Applications

• Plastic injection and pressure die-casting moulds, extrusion

dies

• Surgical tools

• Cutlery and kitchenware

• Maritime components

• Spindles and screws

• General engineering

Available Colors

| Max. Size: | 210x210x320 mm |

| Ship within: | 5 working days |

Material Description

PETG is now widely available as a filament for FDM 3D printers and, thanks to its material properties, has become popular in a number of different professional applications.

When working on new concepts, designers and engineers can take advantage of its transparency, moisture and chemical resistance to make great functional prototypes such as containers for liquids, signage and graphic displays, enclosures for electrical equipment, etc. The most obvious use of PETG 3D printing is for the design and prototyping of the packaging for consumer products that will be later made out of some form of PET when it enters mass production.

Also suited for more demanding environments, where heat and chemical resistance is required in addition to mechanical resistance, machinists and manufacturing engineers can use PETG to create durable custom parts such as manufacturing tools and aids, testing components or robotic end effectors.

Additionally, because PETG remains a durable and performant polymer, engineers and machinists can create true end-use parts including snap fits and living hinges, protective guards or custom machine parts.

ADVANTAGES

➜ Chemical Resistant - PETG’s chemical resistance is the primary reason it is so commonly used as packaging for food, beverages, and consumer goods.

➜ Durable and Flexible - PETG’s flexibility gives it superior durability when compared with materials like PLA.

➜ Moisture Resistance - Moisture resistance, in addition to aiding in the packaging of beverages, makes PETG a good choice for outdoor applications

➜ Surface Finish - Glossy surface finish can be a major selling point for certain appearance model applications.

Available Colors

| Max. Size: | 210x210x200 mm |

| Ship within: | 3 working days |

Material Description

The Soft-Flexible PLA filament is a flexible filament with durable rubber properties. It is useful for making parts that need to be flexible, not to break when bent (resistant) and also to be durable.

Standard PLA (polylactic acid) is a biodegradable plastic obtained from natural resources, in particular from starch extracted from corn, beet and wheat. This material is one of the most widely used materials in 3D printing today because it does not give off harmful gases and is easy to print on. The ease of use of this material derives from different factors:

- It does not require a warm bed, although if available, it is recommended to use it at about 60 ºC.

- It is generally printed at low temperatures (between 190ºC and 220ºC).

- It is a material with almost no warping (warping is the deformation of the pieces with respect to the base).

Available Colors

| Max. Size: | 210x210x303 mm |

| Ship within: | 2 working days |

Material Description

Glass-filled Nylon is mainly used for technical projects, which makes it really popular in industries. Indeed, Nylon 3200 Glass-filled (glass-filled nylon) is a great 3D printing material that allows for creating complex and resistant 3D printed models. It is durable and strong that’s why it perfectly fits technical uses.

Complex models can be 3D printed in glass-filled nylon, just as enclosed volumes. However, keep in mind that the surface of the glass-filled polyamide 3D printed objects is limited to 100 µm that means fine details will not be optimally printed. Nylon 3200 Glass-filled (glass-filled nylon) is indeed an engineering material that is used for technical parts that require particular stiffness, high heat distortion temperature and low abrasive wear, which is a good solution if you are looking for an alternative to parts created using plastic injection.

Available Colors

| Max. Size: | 200x250x330 mm |

| Ship within: | 5 working days |

COPYRIGHT © 2025 PLANFAB.EU. ALL RIGHTS RESERVED.

Powered by 3D ABAX.