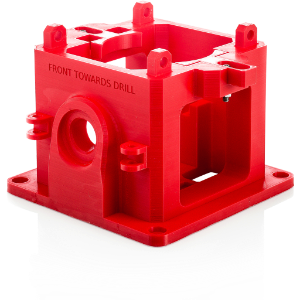

Material Description

Tough PLA is a technical PLA (polylactic acid) material with a toughness similar to ABS. It is ideal for printing functional prototypes and tooling at larger sizes – without fear of delamination or warping. Our Tough PLA offers the same safe and easy use as regular PLA.

Summary

Our Tough PLA filament is formulated to be an easy-to-use technical plastic:

-

Greater machinability than PLA allows more post-processing techniques

-

Similar strength and higher stiffness compared to ABS

-

No delamination or warping for reliable printing of larger parts

-

Compatible with PVA and Breakaway support materials for full geometric freedom

Properties

Tough PLA:

-

Good flexural strength (78 MPa)

-

Good impact strength (Izod tested to 9 kJ/m²)

-

High hardness (79 Shore D)

-

Melting temperature (151 °C)

Applications

Tough PLA provides a durable material solution for:

-

Functional prototyping

-

Tooling

-

Manufacturing aids

Available Colors

| Max. Size: | 330x240x300 mm |

| Ship within: | 7 working days |

Material Description

ABS (acrylonitrile butadiene styrene) is formulated to minimize warping and ensure consistent interlayer adhesion. ABS material is a great choice for creating functional prototypes and complex end-use parts.

Summary

We’ve optimized Ultimaker ABS to make it easier to print with than other ABS filaments:

-

Good interlayer adhesion, especially when printing with an enclosed front

-

Withstands temperatures of up to 85 °C

-

Achieve aesthetic detail that rivals injection molded parts

-

Dual extrusion with a choice of 10 ABS colors, or with Breakaway support material

Properties

Ultimaker ABS material properties include:

-

Good flexural strength (70.5 MPa)

-

High impact strength (Izod tested to 10.5 kJ/m²)

-

High hardness (76 Shore D)

-

High melting temperature (from 225 °C)

Applications

ABS is a versatile 3D printing material. It can be used for:

-

Visual and functional prototyping

-

Fit testing

-

Tooling

-

End-use parts

-

Concept models

-

Custom components

-

Short-run manufacturing

Available Colors

| Max. Size: | 330x240x300 mm |

| Ship within: | 7 working days |

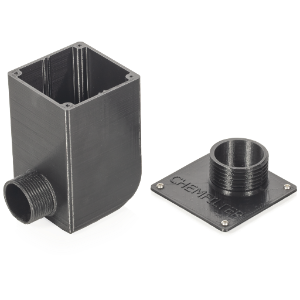

Material Description

Nylon is a polyamide grade based on PA6/66. It features reduced humidity absorption and longer shelf life compared to other nylon filaments. Able to withstand significant mechanical stress, nylon material is a great choice for 3D printing tools, functional prototypes, and end-use parts.

Summary

Our nylon filament works seamlessly with Ultimaker 3D printers thanks to thousands of hours of testing.

-

Impact and abrasion-resistant

-

Low friction coefficient

-

Corrosion-resistant to alkalis and organic chemicals

-

Prints in dual extrusion with PVA or Breakaway

Properties

Ultimaker Nylon material has the following properties:

-

Excellent impact strength (Izod tested to 34.4 kJ/m²)

-

Good ductility (210% elongation at break)

-

Melting temperature (from 185 °C)

Applications

Ultimaker Nylon is ideal for the following applications:

-

Functional prototyping

-

Tooling

-

Industrial modeling

-

End-use parts

Available Colors

| Max. Size: | 330x240x300 mm |

| Ship within: | 7 working days |

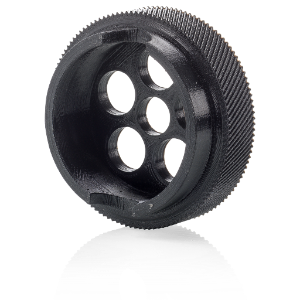

Material Description

CPE (co-polyester) material is an ideal choice for 3D printing functional prototypes and mechanical parts. This filament is formulated for chemical resistance, toughness, and reliable dimensional stability.

Summary

Ultimaker CPE material is developed for a seamless experience with Ultimaker hardware.

-

Excellent chemical resistance

-

High toughness and dimensional stability

-

High impact strength

-

A range of colors to choose from, including grayscale for professional-looking models

Properties

Below are a few of Ultimaker CPE's key mechanical properties:

-

Good flexural strength (Flexural modulus of 2100 MPa)

-

Good tensile strength (Tensile stress at break 38 MPa)

-

High impact strength (Izod tested to 95 J/m)

-

High hardness (Rockwell 108)

Applications

Similar to PET and PETG, Ultimaker CPE is ideal for a range of applications:

-

Visual and functional prototyping

-

Short-run manufacturing

-

Custom components

-

Fit testing

-

Tooling

Available Colors

| Max. Size: | 330x240x300 mm |

| Ship within: | 7 working days |

Material Description

CPE+ material is chemical resistant with high dimensional stability, with the added advantages of increased temperature resistance and higher impact strength compared to regular CPE.

Summary

CPE+ 3D printing filament is more wear resistant compared to regular CPE material, for extremely tough and dimensionally stable functional prototypes that can withstand high temperatures.

-

Can withstand temperatures up to 100 °C

-

Higher impact strength than regular CPE

-

High toughness and dimensional stability for good mechanical performance

-

Excellent chemical resistance

Properties

Ultimaker CPE+ has the following properties:

-

Good flexural strength (64 MPa)

-

High impact strength (Izod tested to 860 J/m)

-

High hardness (111 Rockwell)

Applications

Ultimaker CPE+ is ideal for these applications:

-

Custom components that need to withstand high temperatures

-

Visual and functional prototyping

-

Short-run manufacturing

-

Fit testing

Available Colors

| Max. Size: | 330x240x300 mm |

| Ship within: | 7 working days |

Material Description

PC (polycarbonate) material, print parts that are tough, strong, and retain dimensional stability when subjected to temperatures as high as 110 ºC. Our polycarbonate 3D printing material properties make it perfect for printing molds, tools, functional prototypes, and parts for short-run manufacturing.

Summary

Ultimaker PC material is a top choice material for engineers and manufacturers who require parts that need to retain its strength, toughness, and shape while operating in high-temperature environments.

-

Resists temperatures and retains form up to 110 ºC

-

Flame retardant characteristics

-

Transparent option for translucent parts

-

High toughness, especially for non-transparent options

Properties

-

Good tensile strength (59.7 MPa at break)

-

High impact strength (Charpy tested to 3.41 J/m)

-

High melting temperature (Mass flow rate at 300 °C: 23 - 26 g/10 min)

-

Glass transition at 112 - 113 ºC

Applications

-

Functional prototyping

-

Tooling

-

Molds

-

Short-run manufacturing

-

Industrial modeling

-

End-use parts

Available Colors

| Max. Size: | 330x240x300 mm |

| Ship within: | 7 working days |

Material Description

PP (polypropylene) is a durable, chemical resistant material. It has exceptional fatigue resistance, high levels of toughness, and a low-friction co-efficient. From electrical components to living hinges, PP is the go-to material for prototyping and end-use parts.

Summary

Ultimaker PP material properties make it popular with engineers and manufacturers worldwide. For example, the filament's chemical resistance makes it ideal for 3D printing bottles and containers as functional prototypes that can hold a liquid product.

-

Chemically resistant to a wide range of acids and bases, including industrial cleaning agents

-

Retains its form after torsion, bending, or flexing

-

High electrical resistance for good electrical insulation

-

Low density, resulting in lightweight parts

Properties

Choose Ultimaker PP filament and your 3D printed part will have some impressive properties:

-

High strength-to-weight ratio

-

Shore D hardness of 45

-

27.1 kJ/m² izod impact strength

-

200% elongation at break

Applications

Ultimaker PP material is often chosen for the following applications:

-

Functional prototyping

-

Tooling

-

End-use parts

-

Concept models

Available Colors

| Max. Size: | 330x240x300 mm |

| Ship within: | 7 working days |

Material Description

PVA (polyvinyl alcohol) is a leading water-soluble support material for multi-extrusion 3D printing. It offers you freedom and convenience: to design complex model geometries that require supports, which dissolve away in tap water.

Summary

Ultimaker PVA is at the heart of our market-leading dual extrusion 3D printing experience.

-

Reliable adhesion to PLA, Tough PLA, CPE, and Nylon

-

Non-toxic formula dissolves in regular tap water which can be disposed of safely

-

100% biodegradable with no hazardous by-products

-

Good thermal stability gives better degradation resistance compared to other PVA filaments

-

Properties

Ultimaker PVA has the following properties:

-

Melting temperature 163 ºC

-

Water-soluble support material

Applications

Many applications can benefit from using Ultimaker PVA support material:

-

Parts with complex geometries and internal cavities

-

Concept models

-

Molds

Available Colors

| Max. Size: | 330x240x300 mm |

| Ship within: | 7 working days |

Material Description

Breakaway support is easy and quick to remove. It leaves behind a smoother quality finish than other support materials, with no further post-processing needed.

Summary

We have formulated and tested Ultimaker Breakaway to work seamlessly together with other materials.

-

No sanding ensures high dimensional accuracy – ideal for tight-tolerance parts

-

No waiting for support material to dissolve

-

Longer shelf life and less moisture-sensitive compared to PVA

-

High-quality surface finish on your model

Applications

Ultimaker Breakaway is a versatile support material for many applications, including:

-

Parts made from build materials that are moisture-sensitive or not compatible with Ultimaker PVA

-

Tight-tolerance gauges that should not be post-processed

-

Tools where unremoved Breakaway can provide high-contrast labeling

compatibility

It is compatible for dual extrusion with:

-

PLA

-

Tough PLA

-

ABS

-

Nylon

-

CPE

-

CPE+

Available Colors

| Max. Size: | 330x240x300 mm |

| Ship within: | 7 working days |

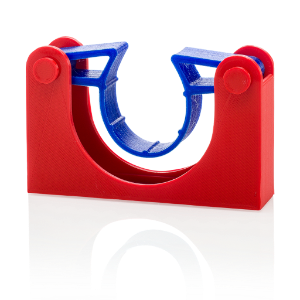

Material Description

TPU 95A (thermoplastic polyurethane) is a flexible material, making it ideal for applications that demand chemical resistance and the qualities of rubber and plastic. For a seamless 3D printing experience, we’ve engineered Ultimaker TPU 95A to be easier and faster to print than other TPU filaments on the market.

Summary

Ultimaker TPU 95A material is an ideal 3D printing material when durability and flexibility are essential.

-

Exceptional wear and tear resistance

-

Rubber-like flexibility

-

Great choice for industrial coatings or prototyping consumer products

Properties

We have developed our TPU filament to have some impressive properties:

-

Shore A hardness of 95

-

Up to 580% elongation at break

-

Good corrosion resistance to common industrial oils and chemicals

Applications

A wide range of applications are made possible with Ultimaker TPU 95A:

-

Functional prototyping

-

Tooling

-

End-use parts

-

Concept models

-

Custom components

-

Fit testing

Available Colors

| Max. Size: | 330x240x300 mm |

| Ship within: | 7 working days |

Material Description

PLA (polylactic acid) is highly versatile, easy to print, and available in 11 colours. It prints reliably with high dimensional accuracy and a quality surface finish. This makes it an ideal material for a range of applications – from detailed prototypes to simple manufacturing jigs and gauges.

Summary

We extensively test our PLA material for hassle-free 3D printing.

-

Easy to print at high print speeds

-

Achieve excellent tensile stiffness and detailed surface quality

-

Dual extrude in two colours, or with PVA or Breakaway.

-

Ideal for investment casting to create metal parts

Properties

Some of the key mechanical properties of Ultimaker PLA include:

-

Excellent flexural strength (103 MPa)

-

Good impact strength (Izod tested to 5.1 kJ/m²)

-

High hardness (83 Shore D)

-

Low melting temperature (from 145 °C)

Applications

Ultimaker PLA is ideal for a wide range of applications, including:

-

Manufacturing aids

-

Architectural models

-

Medical visualization aids

-

Casts and molds for metal or ceramic parts

-

Concept models

-

Educational projects

Available Colors

| Max. Size: | 330x240x300 mm |

| Ship within: | 7 working days |

COPYRIGHT © 2025 PLANFAB.EU. ALL RIGHTS RESERVED.

Powered by 3D ABAX.