- PLA

- PETG - Hyper speed -( 12 x faster )

- Nylon

- PETG

- Carbon Fibre

- ABS

- Polycarbonate

- Resin

- PLA Professional

- PETG + CF

- AIR PLA

- Hyper-Speed PLA-( 12 x faster )

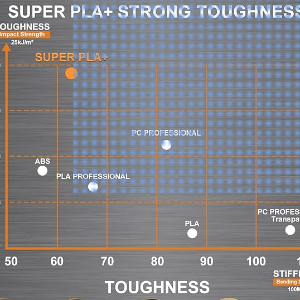

- Super PLA

- PLA - Hyper Speed Large -( 12 x faster )

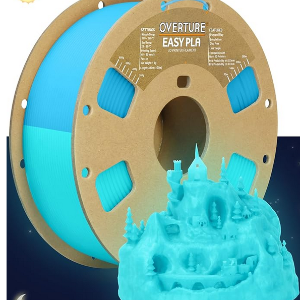

- Luminous Easy PLA

- ABS Hyper-Speed -( 12 x faster )

- PA12 Nylon

- PETG - Hyper Speed - Larger Format ( 12 x faster )

- ABS Hyper-Speed - Larger Format -( 12 x faster )

- ASA

- TPU - 70A

Material Description

Polylactic Acid (PLA) filament is a type of thermoplastic aliphatic polyester widely used in 3D printing. It is derived primarily from renewable resources like corn starch or sugarcane, making it more environmentally friendly compared to petroleum-based plastics.

Characteristics

-

Biodegradability: One of the most significant advantages of PLA is its biodegradable nature. Under the right conditions, it can decompose into lactic acid, a naturally occurring compound.

-

Low Melting Temperature: PLA has a relatively low melting temperature (around 180°C to 220°C). This property makes it easier to print with, requiring lower energy and making it suitable for use with most 3D printers.

-

Rigidity and Strength: PLA filaments are rigid and provide good detail, making them ideal for a wide range of printing applications. However, they are more brittle compared to ABS (Acrylonitrile Butadiene Styrene), another popular 3D printing material.

-

Color and Transparency: It offers a wide range of colors and degrees of transparency. The aesthetic versatility of PLA is one of its appealing aspects.

-

Odorless: During printing, PLA doesn’t emit a strong odor, unlike some other thermoplastics, making it more suitable for use in homes and schools.

Applications

- Prototyping and Educational Projects: Due to its ease of use and low cost, PLA is widely used in educational settings and for prototyping.

- Consumer Products: Items like phone cases, containers, and decorative objects are commonly made from PLA.

- Biomedical Applications: Its biodegradable nature makes it a candidate for temporary implants and other medical devices.

Environmental Impact

While PLA is biodegradable, this process is not as straightforward as it may seem. Industrial composting facilities, with high temperatures and controlled conditions, are required for efficient decomposition. Thus, in typical landfill conditions, PLA might not degrade any faster than conventional plastics.

Storage and Handling

PLA filaments absorb moisture from the air, which can affect printing quality. It's recommended to store them in a cool, dry place, and preferably in airtight containers with desiccants to prolong their usability.

Request a Sample Part

Available Colors

| Max. Size: | 350x350x410 mm |

| Ship within: | 7 working days |

Material Description

PETG is a Glycol Modified version of Polyethylene Terephthalate (PET), which is commonly used to manufacture water bottles. It is a semi-rigid material with good impact resistance, but it has a slightly softer surface which makes it prone to wear.

Advantages

- Excellent layer adhesion.

- Warp resistance.

- Reduced shrinkage.

- Higher density.

- Chemical resistance to both acidic and alkali compounds.

- Flexible printing on glass, acrylic, glass, blue tape and polyimide tape.

- Odorlessness during printing.

REQUEST A SAMPLE PART

Available Colors

| Max. Size: | 200x200x250 mm |

| Ship within: | 5 working days |

Material Description

This filament is commonly used for semi-flexible and mechanical parts since its chemical, wear and UV resistance is higher compared with basic 3D printing plastics. The downside of nylon filament is its tricky behavior when used with some desktop FDM machines.

If printed thin enough, it can provide decent flexibility while maintaining toughness. Nylon's low coefficient of friction also means it's well suited for making functional moving parts. Therefore, nylon is often used for making functional prototypes, living hinges, gears, and similar end-use parts.

How strong are nylon 3D prints?

Also remember to print in an enclosed environment for best results. Nylon is a great material for making structural parts. Compared to ABS with a tensile strength of 4,700 psi, nylon's estimated tensile strength of 7,000 psi is head and shoulders above ABS

Available Colors

| Max. Size: | 350x350x410 mm |

| Ship within: | 7 working days |

Material Description

PETG is a Glycol Modified version of Polyethylene Terephthalate (PET), which is commonly used to manufacture water bottles. It is a semi-rigid material with good impact resistance, but it has a slightly softer surface which makes it prone to wear.

Advantages

- Excellent layer adhesion.

- Warp resistance.

- Reduced shrinkage.

- Higher density.

- Chemical resistance to both acidic and alkali compounds.

- Flexible printing on glass, acrylic, glass, blue tape and polyimide tape.

- Odorlessness during printing.

REQUEST A SAMPLE PART

Available Colors

| Max. Size: | 350x350x410 mm |

| Ship within: | 7 working days |

Material Description

Carbon fiber filaments are composite materials formed by infusing fragments of carbon fiber in a polymer base, similar to metal-infused filaments but with tiny fibers instead. The polymer base can be of different 3D printing materials, such as PLA, ABS, PETG, or nylon, among others.

Available Colors

| Max. Size: | 350x350x410 mm |

| Ship within: | 7 working days |

Material Description

ABS filament is a common 3D printing material for a variety of reasons. ABS filament is an extremely durable thermoplastic. It is commonly used in rapid prototyping and additive manufacturing environments to test product impact resistance and durability. ABS has strong electrical insulation properties.

some of the characteristics of ABS filament

- Strength. High.

- Flexibility. Medium.

- Durability. High.

- Difficulty to Use. Medium.

- Print Temperature. 210°C – 250°C.

- Print Bed Temperature. 80°C – 110°C.

- Shrinkage / Warping. Possible – care required; print with heated bed.

- Soluble. In esters, ketones, and acetone.

Available Colors

| Max. Size: | 350x350x410 mm |

| Ship within: | 7 working days |

Material Description

Polycarbonate, better known by its acronym PC, is a material renowned in the 3D printing market for its impact resistance and transparency. It is a lightweight yet strong thermoplastic, ideal for a wide range of professional applications.

Why is polycarbonate good for 3D printing?

Polycarbonate is known for its strength and durability. It has very high heat and impact resistance making it an ideal choice for tough environments.

Available Colors

| Max. Size: | 350x350x410 mm |

| Ship within: | 7 working days |

Material Description

Resin 3D printing is the technology in which liquid resin is stored in a container instead of being injected through a nozzle. The major terms or types of resin 3D printing include Stereolithography (SLA), Digital Light Processing, and Liquid Crystal Display (LCD) or Masked Stereolithography (MSLA).

Available Colors

| Max. Size: | 180x180x180 mm |

| Ship within: | 7 working days |

Material Description

- -- Our Overture PLA Professional is an advanced PLA filament with similar stiffness as regular PLA and dramatically improved fracture toughness (Charpy Impact Strength 13.4+/-1.2 kJ/m2, 5 times tougher than regular PLA). Optimized printing quality, high purity with low shrinkage and superb layer bonding, meeting your demands for printing projects of functional parts with higher toughness

- --- Designed and Manufactured with Clog-Free patent to guarantee a smoother and more stable printing experience with Overture PLA Plus Rolls. Complete drying for 24 hours before packaging and vacuum sealed with desiccants in nylon re-sealable bag, no bubble and easy to print. Full mechanical winding and strict manual examination, to make sure the line tidy and less-tangle, so as to avoid possible snap and line breaking

- --- Advanced CCD diameter measuring and self-adaptive control system in the manufacturing guarantee these tough PLA filaments to be strict tolerances. Diameter 1.75mm, dimensional accuracy (99%) + / - 0.03 mm without any exaggeration; 1 kg spool (2.2lbs)

- --- With over 8 years' 3D filaments R & D experience, thousands tons of filaments output every month, Overture is capable of manufacturing all kinds of filaments in large scale with premium quality, which contribute to Overture filament cost-effective and reliable for most common 3D printers, such as MK3, Ender 3, Monoprice FlashForge and more

- ISO 9001 2015 Quality Control

Available Colors

| Max. Size: | 350x350x410 mm |

| Ship within: | 7 working days |

Material Description

CarbonX™ PETG+CF Carbon Fiber Reinforced Co-Polyester. CarbonX™ PETG+CF is made in the USA using premium PETG and High-Modulus Carbon Fiber (not carbon powder or milled carbon fiber). Extruder Temp. 230-260°C.

42 MPa

PETG CF Safety Datasheet

| General information | |

|---|---|

| Tensile strength (ISO 527) | 42 MPa |

| Tensile Modulus (ISO 527) | 4700 MPa |

| Flexural strength | - |

| Flexural modulus (ISO 178) | 3800 MPa |

Available Colors

| Max. Size: | 350x350x410 mm |

| Ship within: | 7 working days |

Material Description

- Foaming Process: - AIR PLA is a low-density foamed PLA, the foaming process allows the filament to have a lower density than ordinary PLA, making the print quality lighter (compared to about 80% of the weight of ordinary PLA)

- Easy to Print & More Humanized Design: -- Easy to print just like normal PLA, more likely to get quality prints with sharp details. Excellent threshold overhang angle. Raft and support are very easy to remove; Reel with length/ weight gauge and viewing hole so that you can easily figure out the remaining filaments; more filaments clip holes for fixing purpose on the reel; Larger spool inner diameter design makes feeding smoother

- Odorless & No Bubble-- Developed based on Natural PLA, this Matte PLA filaments deliver excellent printing quality with no odor and low warpage during printing; Complete drying for 24 hours before vacuum packaging to effectively protect the filament from moisture, no stringing and bubble-free

- Dimensional Accuracy & Consistency-- advanced CCD diameter measuring and self-adaptive control system in the manufacturing guarantee these PLA filaments of 1.75mm diameter, dimensional accuracy +/-0.03mm; 1 kg spool(2.2lbs)

- Cost-effective and Wide Compatibility-- With over 8 years’ 3D filaments R & D experience, thousands tons of filaments output every month, Overture is capable of manufacturing all kinds of filaments in large scale with premium quality, which contribute to Overture filament cost-effective and reliable for most common 3D printers, such as MK3, Ender 3, Monoprice FlashForge and more

ISO 9001 2015 Quality Control

Available Colors

| Max. Size: | 350x350x410 mm |

| Ship within: | 7 working days |

Material Description

Polylactic acid, also known as PLA, is a thermoplastic monomer derived from renewable, organic sources such as corn starch or sugar cane. Using biomass resources makes PLA production different from most plastics, which are produced using fossil fuels through the distillation and polymerization of petroleum.

Available Colors

| Max. Size: | 200x200x250 mm |

| Ship within: | 5 working days |

Material Description

- High Properties : - SUPER PLA + filament greatly improves impact resistance, has mechanical properties that ordinary PLA has not improved, and steel toughness is balanced. At the same time, SUPER PLA + also has the easy printing performance of PLA material, the combination of the two points makes it an excellent substitute for ABS (when the heat resistance of PLA can meet the requirements)

- Clog-Free, Bubble-Free & Easy-to-use: - Designed and Manufactured with Clog-Free patent to guarantee a smoother and more stable printing experience with Overture SUPER PLA + Rolls. Complete drying for 24 hours before packaging and vacuum sealed with desiccants in nylon re-sealable bag, no bubble and easy to print. Full mechanical winding and strict manual examination, to make sure the line tidy and less-tangle, so as to avoid possible snap and line breaking

- Application: -Make prints with impact resistance and bending resistance requirements. Including machine parts, drone accessories, remote control car anti-collision accessories, brackets, model prototypes, hooks, etc

- Cost-effective and Wide Compatibility: -With over 9 years' 3D filaments R & D experience, thousands tons of filaments output every month, Overture is capable of manufacturing all kinds of filaments in large scale with premium quality, which contribute to Overture filament cost-effective and reliable for most common 3D printers, such as MK3, Ender 3, Monoprice FlashForge and more

- ISO 9001 2015 Quality Control

Available Colors

| Max. Size: | 350x350x410 mm |

| Ship within: | 7 working days |

Material Description

Polylactic acid, also known as PLA, is a thermoplastic monomer derived from renewable, organic sources such as corn starch or sugar cane. Using biomass resources makes PLA production different from most plastics, which are produced using fossil fuels through the distillation and polymerization of petroleum.

Available Colors

| Max. Size: | 300x300x300 mm |

| Ship within: | 3 working days |

Material Description

- Luminous EASY PLA - This new Luminous EASY PLA contains glow fillers that glow in the dark after absorbing light energy. Please avoid long exposure to direct sunlight in order to have longer usage lifespan

- Good Layer Adhesion- No warping, no jamming, no blobs or layer delamination issues. This Luminous filament is a worry-free glow PLA filament which has great bed adhesion, very consistent color and dimensional accuracy

- Tangle Free & Moisture Free - OVERTURE Luminous PLA is carefully winded to avoid any tangling issues, dried and vacuum sealed in a resealable ziplock bag with desiccant. Please make sure to NEVER let go the tip of the filament as it may create nodes tangle issue. Holes on the side edge of the spool can be used to prevent this issue

- Printing Settings - Nozzle: 190-210˚C; Bed: 25-60˚C; Speed: 40-90mm/s. Glow in the dark PLA filament

- Ready for Festivals & Parties - This Luminous PLA filament can make prints that has a glow effect in the dark, ideal for printing glow sticks, figurines, party decoration piece, Halloween decorations, Christmas ornaments or gift for kidsble 3d filaments /accessories/3d printer/3d pen supplier 3d printer filament white easy pla 3d printer filament 1.75 pla spool 3-d printer filament 1kg pla filament mk3 1.75 filament 3d printer accessories 3d art ender 3 pla filament Engineering Maker Layer adhesion prototyping PLA roll polylactic acid

- ISO 9001 2015 Quality Control

Available Colors

| Max. Size: | 350x350x410 mm |

| Ship within: | 7 working days |

Material Description

Hyper Speed ABS

The ABS thermoplastic composition of Hyper Speed material is subjected to a meticulously controlled heating process. This transformative procedure guarantees the seamless fusion of each layer, establishing a robust and flawless base for your design endeavors.

Cost-Effective Excellence Attain unmatched print quality without being burdened by financial limitations, positioning Hyper Speed ABS as a beacon of cost-effective innovation. Dominant Presence: Hyper Speed ABS boasts an impressive 80% market share in the world of 3D printed items, a testament to its unparalleled versatility.

Testing Method: ISO 1183, GB/T 1033

Available Colors

| Max. Size: | 200x200x250 mm |

| Ship within: | 5 working days |

Material Description

PA12, also known as Nylon 12, is a versatile and widely used thermoplastic material with a range of applications across various industries. It belongs to the polyamide (PA) family of plastics and is known for its exceptional properties. Here's a detailed description of PA12 Nylon:

Chemical Composition: PA12 is a synthetic polymer made from the polymerization of laurolactam monomers. Its molecular structure consists of a repeating unit of amide groups, which gives it its characteristic properties.

Physical Properties:

-

High Strength: PA12 Nylon is renowned for its excellent tensile strength, making it a robust and durable material. It can withstand significant mechanical stresses and loads.

-

Flexibility: Despite its strength, PA12 Nylon is relatively flexible, allowing it to endure bending and twisting without breaking. This property makes it suitable for applications that require both strength and flexibility.

-

Low Friction: PA12 has a low coefficient of friction, making it an excellent choice for components that require smooth movement or sliding, such as bearings and gears.

-

Chemical Resistance: It exhibits good resistance to many chemicals, oils, and solvents, making it suitable for use in harsh environments.

-

Low Moisture Absorption: PA12 Nylon has relatively low moisture absorption compared to some other nylon materials. This property helps maintain its mechanical properties in humid conditions.

Thermal Properties:

-

High Melting Point: PA12 has a relatively high melting point, typically around 180-190°C (356-374°F), which allows it to maintain its structural integrity at elevated temperatures.

-

Thermal Stability: It exhibits good thermal stability, making it suitable for applications where it may be exposed to heat over extended periods.

Other Notable Properties:

-

Electrical Insulation: PA12 is an excellent electrical insulator, which makes it suitable for various electrical and electronic applications.

-

Lightweight: It has a low density, making it a lightweight material, which is advantageous in applications where weight is a consideration.

Applications:

PA12 Nylon is used in a wide range of applications, including:

-

Manufacturing: It's used for producing various industrial components, such as gears, bushings, rollers, and pulleys, due to its excellent mechanical properties.

-

Automotive: PA12 is found in automotive components like fuel lines, air intake manifolds, and cable sheathing, thanks to its durability and resistance to automotive fluids.

-

Medical: It's used in medical devices and equipment because of its biocompatibility and resistance to sterilization methods.

-

Consumer Goods: PA12 is used in the production of everyday items like sports equipment, zippers, and luggage due to its strength and flexibility.

-

Aerospace: In aerospace applications, PA12 is used for lightweight structural components and parts that require high strength.

-

3D Printing: PA12 is a popular material for 3D printing, particularly in selective laser sintering (SLS) and Multi Jet Fusion (MJF) technologies, where it can create durable and functional prototypes and end-use parts.

Available Colors

| Max. Size: | 250x250x350 mm |

| Ship within: | 7 working days |

Material Description

PETG is a Glycol Modified version of Polyethylene Terephthalate (PET), which is commonly used to manufacture water bottles. It is a semi-rigid material with good impact resistance, but it has a slightly softer surface which makes it prone to wear.

Advantages

- Excellent layer adhesion.

- Warp resistance.

- Reduced shrinkage.

- Higher density.

- Chemical resistance to both acidic and alkali compounds.

- Flexible printing on glass, acrylic, glass, blue tape and polyimide tape.

- Odorlessness during printing.

REQUEST A SAMPLE PART

Available Colors

| Max. Size: | 300x300x300 mm |

| Ship within: | 3 working days |

Material Description

Hyper Speed ABS

The ABS thermoplastic composition of Hyper Speed material is subjected to a meticulously controlled heating process. This transformative procedure guarantees the seamless fusion of each layer, establishing a robust and flawless base for your design endeavors.

Cost-Effective Excellence Attain unmatched print quality without being burdened by financial limitations, positioning Hyper Speed ABS as a beacon of cost-effective innovation. Dominant Presence: Hyper Speed ABS boasts an impressive 80% market share in the world of 3D printed items, a testament to its unparalleled versatility.

Testing Method: ISO 1183, GB/T 1033

Available Colors

| Max. Size: | 300x300x300 mm |

| Ship within: | 3 working days |

Material Description

The ASA (Acrylonitrile Styrene Acrylate) is a thermoplastic that combines the mechanical robustness, the resistance to UV rays, the resistance to water with a great surface finish, which makes the filament ASA suitable to make final pieces in 3D for machinery or prototypes Durable for outdoor use in the open

Available Colors

| Max. Size: | 350x350x410 mm |

| Ship within: | 7 working days |

Material Description

Filaflex UltraSoft 70A is one of the most elastic and softest filaments on the market, reaching a 900% stretch until breaking. The Filaflex UltraSoft filament is a TPE filament (Thermoplastic Elastomer) with a polyurethane base and certain additives.

The Filaflex Ultrasoft 70A filament has an even higher elasticity and smoothness than the Filaflex 82A (Filaflex), with a Shore 70A hardness and an abrasion resistance of 45mm3, being one of the most elastic and soft filaments on the market. Like the Filaflex, the Filaflex Ultrasoft 70A is resistant to solvents, acetone and fuels, but with lower tensile strength and lower softening temperature. The Filaflex UltraSoft 70A has good bonding properties with other types of materials used in the field of 3D printing, such as PLA, ABS, HiPS and some Nylons, resulting in composite pieces with different properties and hardness. Thanks to all the qualities mentioned above, this material has an infinity of applications in all types of fields

FilaFlex UltraSoft is non-toxic, but not approved for medical or nutritional use. This material doesn't emit odors, is totally odorless and does not produce toxic gases. Due to its high elasticity, it is a complex material to use, since, in certain types of extruders, it's likely to wrap around the pinion of the extruder motor or directly bend the filament already before entering the HotEnd, something that occurs if a Bowden drive system is used. Therefore, this material is recommended only for advanced users and with 3D printers with the Recreus Extruder v3 extruder or with an extruder prepared to print elastic filaments (Should always be direct drive, never bowden). The "Recreus Extruder v3" is a direct-drive extruder extruder with high quality components created by the manufacturer of the Filaflex UltraSoft 70A, to be able to use this and other flexible materials without any problems and at high speeds compared to the rest of extruders on the market . Another extruder compatible with this material, but not recommended by the manufacturer, is the E3D Titan Aero.

Available Colors

| Max. Size: | 300x300x300 mm |

| Ship within: | 3 working days |

Powered by Mitchell and Son Additive Manufacturing Ltd